Sheet Metal Fabrication Service

Get instant quotes on fabrication services for both custom sheet metal prototypes and production. Lead times as fast as 3 days.

- Faster delivery in 3 days

- Middle-small batch sheet metal processing

- Full inspection before delivery ensures quality

Start Sheet Metal Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

Sheet Metal Fabrication Process

SogaWorks’ custom sheet metal fabrication services provide a fast and cost-effective solution for your project needs.

These services encompass bending, laser cutting, and more, and they are for both prototype development and low-volume production runs. Sheet metal fabrication produces robust, end-use metal components, offering a diverse range of materials and finishes to meet your specific requirements.

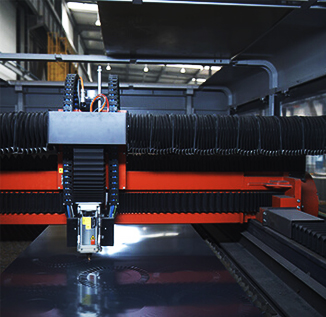

Using a laser beam to cut through various types of sheet metal materials, which is capable of creating intricate designs with smooth finishes and tight tolerance.

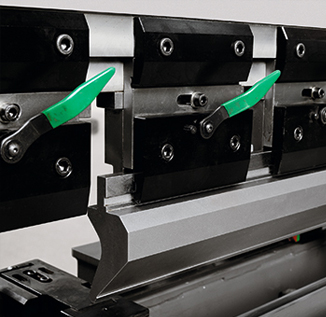

Deforming a sheet metal along a straight axis, creating a V-shape, U-shape, or channel shape. This technology provides precision and repeatability with minimal setup cost.

Auxiliary Process

Press Riveting, Welding, etc

Surface Finishing

Baking Finishing, Plastic Spraying, Electroplating, etc

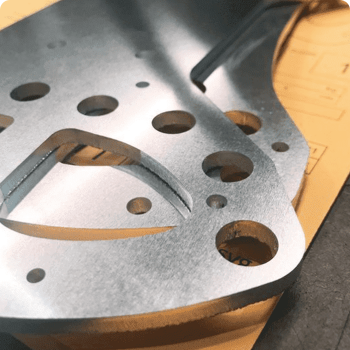

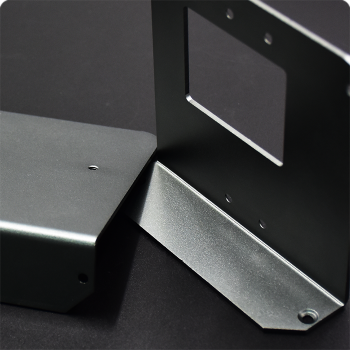

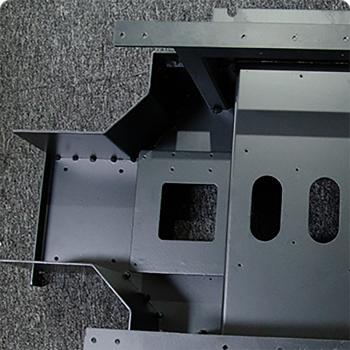

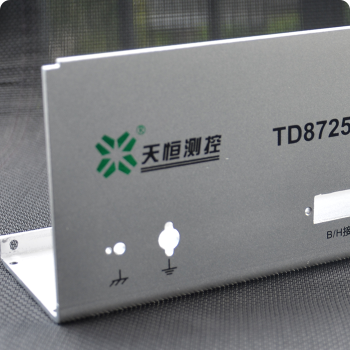

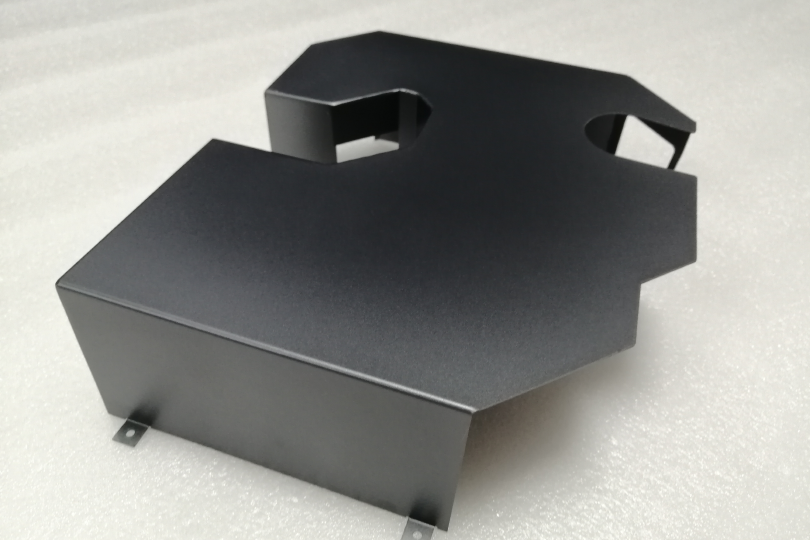

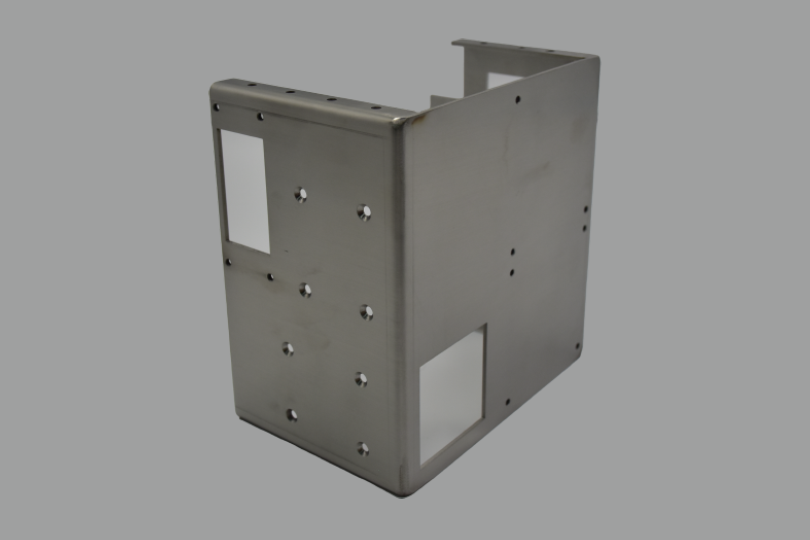

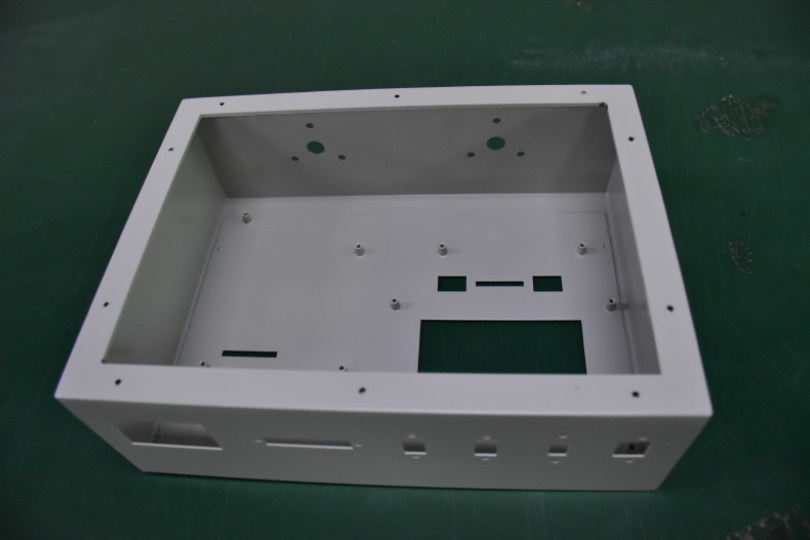

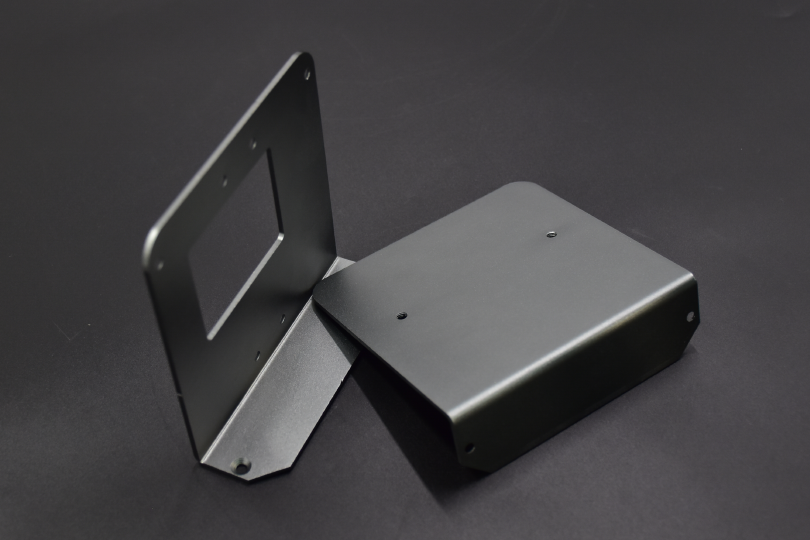

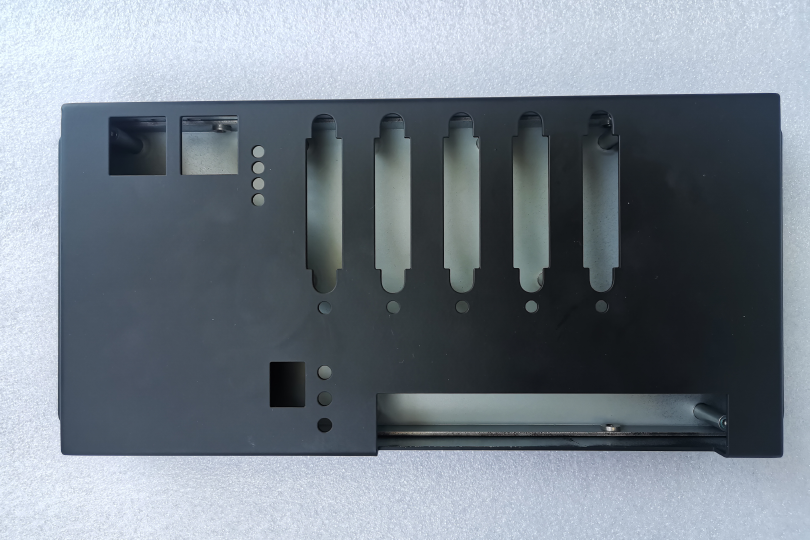

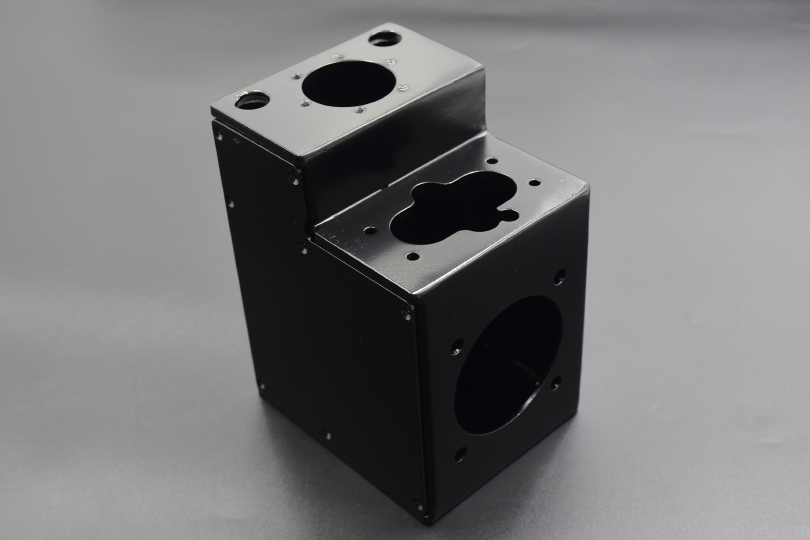

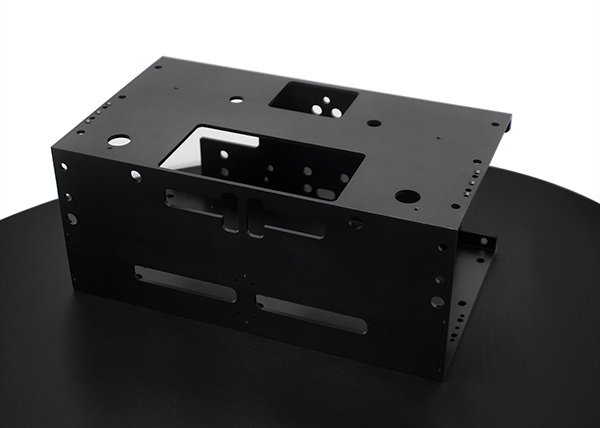

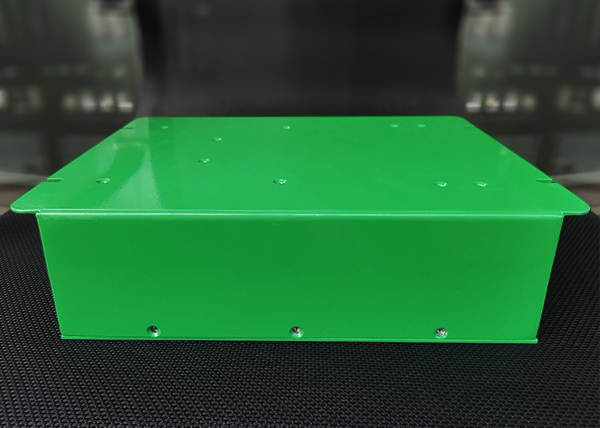

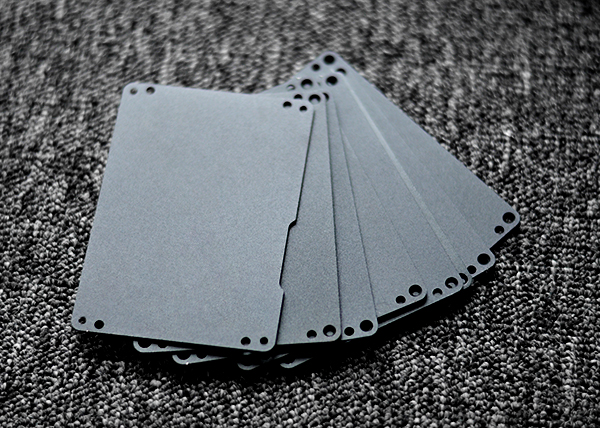

Sheet Metal Fabricated Parts Produced By SogaWorks

Gallery of sheet metal fabricated prototypes and end-use parts we have produced for our valued customers.

Sheet Metal Fabrication Tolerance

Sheet metal tolerances describe the acceptable deviation between features on sheet metal parts to ensure correct and consistent fit in installation or integration. You should provide 2D technical drawings(DWG or DXF format) for us. For anodized (color) or powder coating, unless the desired color is “black”, a RAL or PANTONE number or a sample should be provided. SogaWorks will make the best effort to match the color but cannot guarantee a perfect match.

Dimension Detail |

Tolerance |

|---|---|

|

Hole sizes |

±0.005" |

|

Edge to edge, single surface |

±0.010" |

|

Edge to hole, single surface |

±0.010" |

|

Hole to hole, single surface |

±0.005" |

|

Bend to edge / hole, single surface |

±0.015" |

|

Bend to bend |

±0.020" |

|

Edge to feature, multiple surface |

±0.030" |

|

Over formed part, multiple surface |

±0.030" |

|

Bend angle |

±1° |

Sheet Metal Fabrication Materials

Many materials can be used in sheet metal fabrication technologies, which bring you a wide range of options for your sheet metal parts. At Sogaworks, we provide instant quotations on 40+ industrial-grade metal and plastic materials.

Aluminum

Aluminum possesses key characteristics of lightweight, durability, malleability, making it ideal for intricate designs.

- Aluminum 5052

Stainless steel

Stainless steel is an ideal choice for fabrication, its durability and resistance to staining and corrosion ensure longevity in harsh environments.

- Stainless steel 304

Steel Alloy

Steel alloys are easy to machine and form compared to other materials, allowing for the creation of complex and intricate designs.

– SPCC

– SECC

– SGCC

Brass

Brass has an aesthetic appearance, efficient heat conductivity, and malleability. making it a preferred choice for decorative elements.

- Brass C260

- Brass C274

- Brass C280

- Brass C360

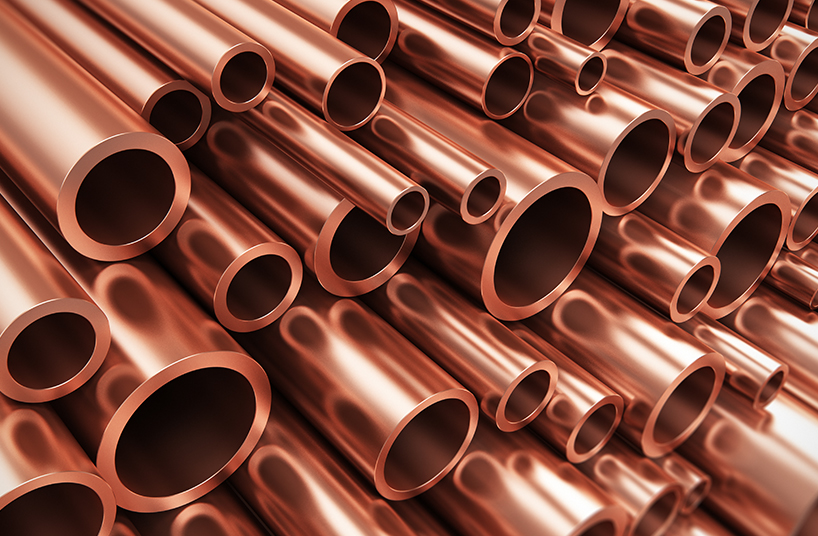

Copper

Copper is resistant to corrosion and a great conductor of electricity and heat. It can be easily welded, allowing for the efficient joining of sheet metal parts.

- Copper C101

- Copper C102

- Copper C110

* For materials not shown here, feel free to contact us directly.

Sheet Metal Fabrication Surface Finishes

We provide diverse finishes for your custom sheet metal parts to enhance durability, corrosion resistance,

and aesthetic appearance. For the finishes not listed below, simply select specify your needs in your quote.

Grow a thickness oxide layer ranging from 0.0001 to 0.001 inches to protect and color aluminum CNC machined parts for corrosion resistance and aesthetics.

Anodizing Type II

Preserve or enhance the electrical conductivity of the aluminum parts while still providing the benefits of traditional type II.

Conductive Anodizing Type II

Apply a protective or functional coating to surfaces. It involves the application of liquid paint and then undergoes a curing process to solidify the paint film.

Painting

Apply a protective and decorative coating to materials, primarily metals. It involves applying a dry powder onto a surface, which is then applied electrostatically and cured under heat or UV light.

Powder Coating

Spray silica sand to the surface of the workpiece using compressed air to clean, smooth, or texture surfaces, providing a desired finish for functional or aesthetic purposes.

Sand Blasting

Apply images, patterns, or text to surfaces.

Silk Screen

Label, engrave, or add information to materials.

Laser Marking

Use abrasive belts or roller brushes to refine and improve the surface quality of the machined components.

Brushing

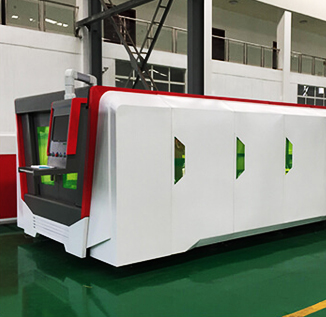

Manufacturing Capabilities and Equipment

- 30+ countries and regions

- 50,000+ customers

- 16,000,000+ parts manufactured in total

- 1,000+ collaborative partner factories

- 4,800+ precision equipment

What Our Customers Say

It was an amazing experience to work with SogaWorks people. They are very professional and caring and keep up smooth communication over our outsourced parts production. We will continue to partner with their service for future projects.

We have lots of projects for small quantity parts. SogaWorks has always treated our requests fairly. What is more, they provided us with valuable technical feedback. We really appreciate their genuine desire to help.

Postdoctoral Scholar, Stanford University

SogaWorks demonstrates professionalism. They enabled our purchasing process at ease. We don't have to juggle around managing various suppliers. You save the day. Great job!

Purchasing Specialist, Panasonic China

We would like to express our thanks for your down-to-earth support on our rush orders. Our requirements were rigid and the delivery deadlines were tight. Yet, all orders have been delivered perfectly. This is a team that can take challenging jobs.

Project Manager, HP

Our Advantages

Quick Online Quotation

Combining bending, laser cutting with machine learning-driven technologies, we can offer rapid quotations for your inquiry. Accelerating project initiation for your sheet metal needs.

Fast Lead Times

With our strong network of qualified manufacturing shops, we provide quick pricing and completed parts as fast as 3 days.

Scalable Volume

We custom fabricate all sheet metal parts as per your requirements, offering a cost-effective setup compared to CNC machining. Whether you need just a single prototype or more, our service is suitable for you.

Online Engineering Support

Enjoy hassle-free services with our engineering report. Our sheet metal engineers ensure the precision and high quality of your project, reducing your workload and checking the product quality.

Serving Multiple Industries

Our rapid prototyping and on-demand production services are used across a wide range of industries, but the following areas are where we have the most experience.

Medical

Elevate the reliability of your medical devices with accurate manufacturing solution.

Aerospace

Lightweight and durable solutions for the most demanding aviation needs.

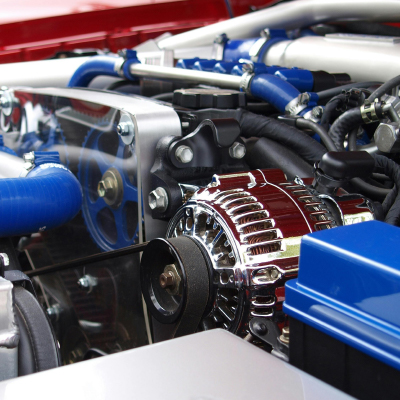

Automotive

Tailored to optimize performance and reliability in the automotive.

Robotics

Fuel your robotic innovations with our precision-engineered parts.

FAQs About Sheet Metal Service

What is the minimum order qty of sheet metal service?

We do not have a minimum order quantity limit for our sheet metal service. Whether you need rapid prototyping or small, medium, or large-scale production, we can accommodate your needs.

What is the K factor in sheet metal?

The K factor in the sheet metal process represents the ratio of the position of the neutral axis to the material thickness. This value varies depending on the physical properties and thickness of the materials used. Understanding the K factor is crucial for accurate bending and forming of sheet metal, as it affects the material’s behavior during these processes. By considering the K factor, manufacturers can achieve precise and consistent results in their sheet metal fabrication projects.

How much does the service cost?

Every aspect of a sheet metal fabrication project entails an associated cost. This includes the design phase, potential prototyping, and finishing processes, among other steps. Beyond the fabrication process itself, the materials used also incur costs. Each element, from initial design to the final finishing touches, contributes to the overall expenditure of the project. By understanding these costs, you can better plan and allocate your budget to ensure a successful and cost-effective fabrication project.