Urethane Casting Service

- Rapid mock-up in as fast as 2 days

- Low volume urethane casting without tooling fee

- Full inspection before delivery

Start Urethane Casting Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

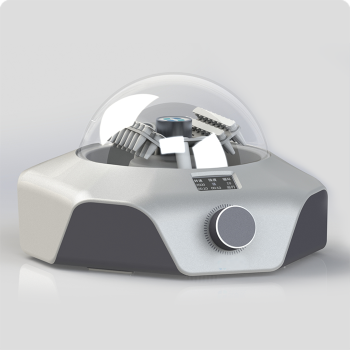

Urethane Casting Process

Rapid Mock-up

As fast as 2 days

Urethane Casting

Low-volume urethane casting without tooling fee.

Surface Finishing

Painting, silk screen,laser marking.

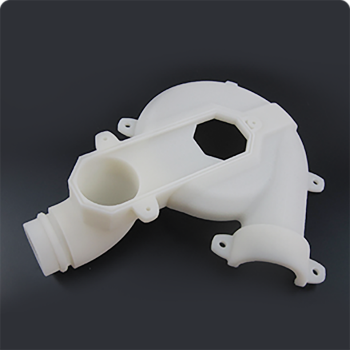

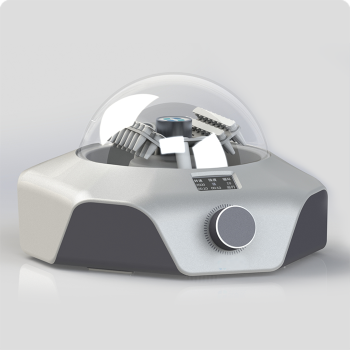

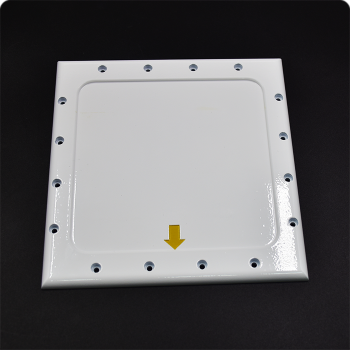

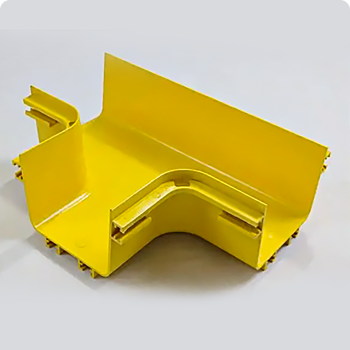

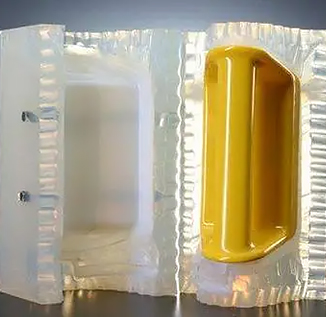

Urethane Casted Parts Produced By SogaWorks

Gallery of urethane cast prototypes and end-use parts we have produced for our valued customers.

Urethane Casting Tolerance

Urethane casting is a fabrication process that uses silicone molds to produce production-grade elastomeric parts with 10-200 units. Typically, ISO 2768-m is used as a manufacturing standard and a shrinkage rate of +0.15% can be expected due to thermal expansion of the liquid and the response of the flexible mold.

Limits for nominal lengths |

ISO 2768-m |

|---|---|

|

0.5mm to 3mm |

±0.1mm |

|

Over 3mm to 6mm |

±0.1mm |

|

Over 6mm to 30mm |

±0.2mm |

|

Over 30mm to 120mm |

±0.3mm |

|

Over 120mm to 400mm |

±0.5mm |

|

Over 400mm to 1000mm |

±0.8mm |

|

Over 1000mm to 2000mm |

±1.2mm |

|

Over 2000mm to 4000mm |

±2.0mm |

Urethane Casting Materials

Plastics

We stock an exclusive range of plastic materials for urethane casted parts.

- ABS-Like

- Acrylic-Like

- Nylon-Like

- PC-Like

- PP-Like

- Rubber-Like

- Clear Rubber-Like

Surface Finishes

Painting

Spray a layer of paint onto the surface of the part.

Apply a protective and decorative coating to materials.

Powder coating

Silk Screen

Apply images, patterns, or text to surfaces.

Use a laser beam to alter the surface to label, engrave, or add information to materials.

Laser Marking

Manufacturing Capabilities and Equipment

- 30+ countries and regions

- 50,000+ customers

- 16,000,000+ parts manufactured in total

- 1,000+ collaborative partner factories

- 4,800+ precision equipment

What Our Customers Say

It was an amazing experience to work with SogaWorks people. They are very professional and caring and keep up smooth communication over our outsourced parts production. We will continue to partner with their service for future projects.

We have lots of projects for small quantity parts. SogaWorks has always treated our requests fairly. What is more, they provided us with valuable technical feedback. We really appreciate their genuine desire to help.

Postdoctoral Scholar, Stanford University

SogaWorks demonstrates professionalism. They enabled our purchasing process at ease. We don't have to juggle around managing various suppliers. You save the day. Great job!

Purchasing Specialist, Panasonic China

We would like to express our thanks for your down-to-earth support on our rush orders. Our requirements were rigid and the delivery deadlines were tight. Yet, all orders have been delivered perfectly. This is a team that can take challenging jobs.

Project Manager, HP

Our Advantages

Quote in 5 Seconds

Utilizing a self-developed, machine learning-driven intelligent quoting system, we can offer rapid quotations for your inquiry in 5s.

One-Stop Manufacturing Service

We provide one-stop manufacturing services from R&D prototypes to massive production, covering hundreds of materials and most of the surface finishes.

End-to-end professional Service

Our specialized account managers and engineers provide “One to One” service, and work collaboratively with both customers and partners by better understanding their requirements, which is to achieve better turnaround time and lower cost for your project.

Fully Inspected Before Delivery

Before shipping out the parts to you, we conduct a strict final inspection for all parts with high-accuracy measuring equipment.

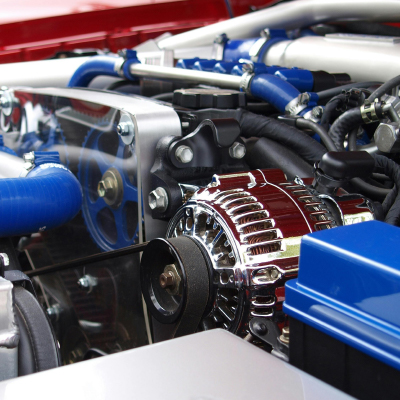

Serving Multiple Industries

Our rapid prototyping and on-demand production services are used across a wide range of industries, but the following areas are where we have the most experience.

Medical

Elevate the reliability of your medical devices with accurate manufacturing solution.

Aerospace

Lightweight and durable solutions for the most demanding aviation needs.

Automotive

Tailored to optimize performance and reliability in the automotive.

Robotics

Fuel your robotic innovations with our precision-engineered parts.

FAQs About Urethane Casting Service

What is the lead time for urethane casting?

Production-level urethane casting typically has lead times of 3 weeks. Although the master pattern and mold can be finished in 1-2 days, meeting production volumes can take longer due to the urethane’s curing time, which cannot be shortened. A single urethane casting mold usually produces 1-10 parts per day, depending on factors like the type of urethane and part geometry.

How does urethane casting work?

Urethane casting is a manufacturing process that involves creating a mold using a master pattern or model, typically made of silicone rubber. A mixture of urethane resin and a curing agent is then poured into the mold cavity, ensuring it is filled completely and that any air bubbles are removed. The urethane is left to cure at room temperature or in an oven, and once it has hardened, the mold is opened, and the cast part is removed and trimmed of any excess material.

What are the tolerances for urethane casting?

The tolerances of cast urethane are usually approximately ± 0.015” or ± 0.003 per inch, whichever is larger. On a case-by-case basis, tighter tolerances might be provided. Generally, a typical shrinkage rate is +0.15%.

What is the difference between urethane casting and injection molding?

Urethane casting uses liquid urethane resins that are poured into a mold, while injection molding uses molten plastic that is injected into a mold. Urethane casting molds are typically made of silicone rubber or other soft materials, while injection molding molds are made of steel or aluminum and are much more durable. Urethane casting is suitable for low to medium production volumes, while injection molding is better suited for high-volume production. Additionally, injection molding can produce parts with more consistent dimensions and tighter tolerances, but the upfront costs for tooling are much higher.