Online Custom CNC Machining Service

Get instant quotes on your custom metal or plastic parts with SogaWorks’ online CNC machining services, choosing from 40+ advanced materials and 20+ surface finishes.

- Rapid prototyping and production

- Quote in 5s with intelligent quotation system

- MOQ 1 PC and as fast as 2 days delivery

- Fully inspected before delivery

Start A New CNC Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

CNC Machining Capabilities

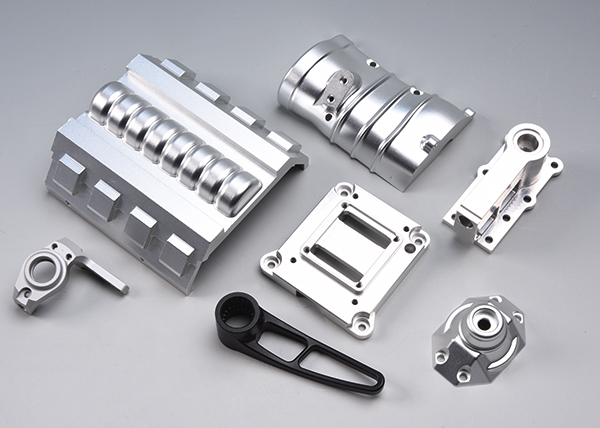

For customers who seek CNC services for rapid prototyping and low-volume production, our custom CNC machining service is the best solution. With our self-owned factories of 2000 ㎡ and a manufacturing network of 1000+ qualified CNC machining shops, we can ensure your CNC machined parts with quality, affordability, and fast lead times.

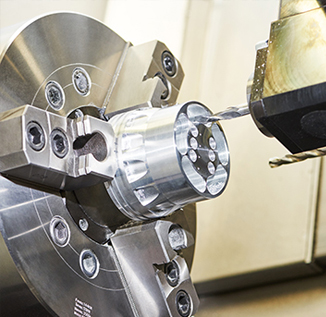

CNC Milling

CNC milling manufactures tight tolerance metal and plastic parts with specific geometries, including 3,4, and 5–axis CNC machining processes.

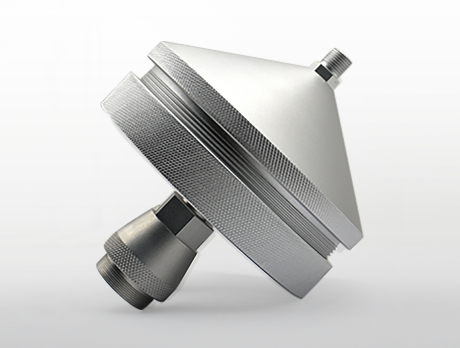

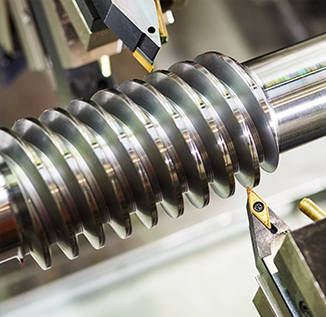

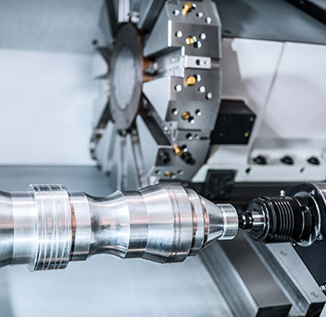

CNC Turning

CNC turning manufactures cylindrical parts from plastic and metal bars or tubes, including CNC turning, Swiss turning and turning-mill machines.

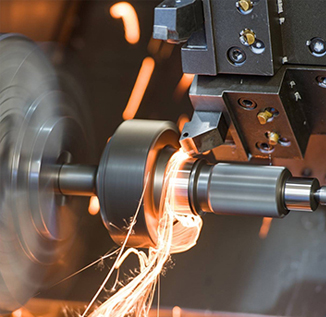

Auxiliary Process

Wire Cutting, EDM, Grinding, etc.

Surface Finishing

Sandblasting, Anodizing,

Electroplating, Polishing, etc.

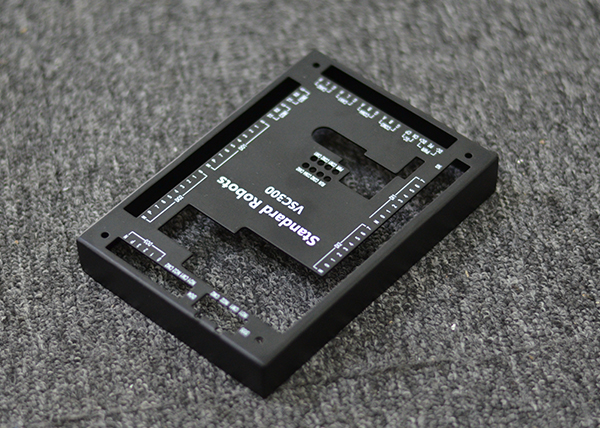

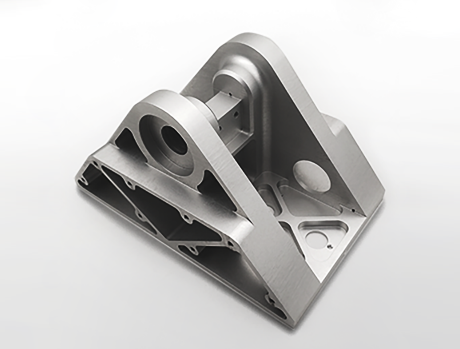

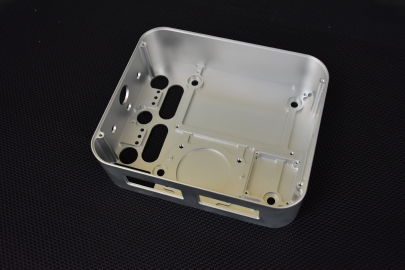

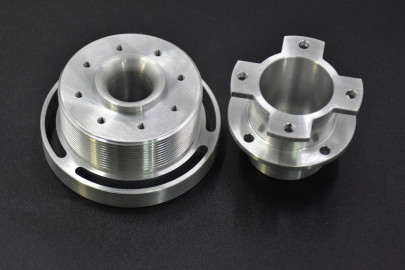

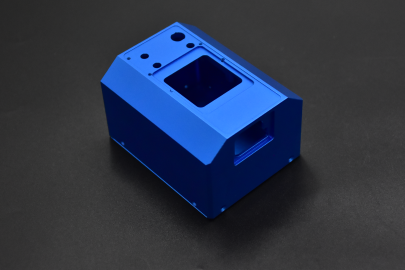

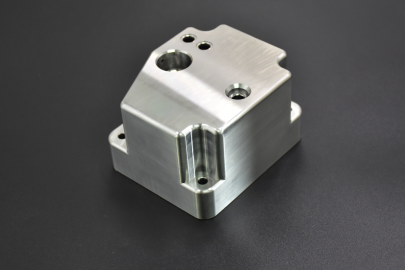

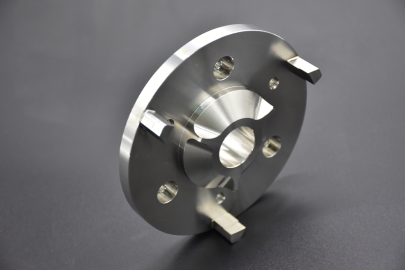

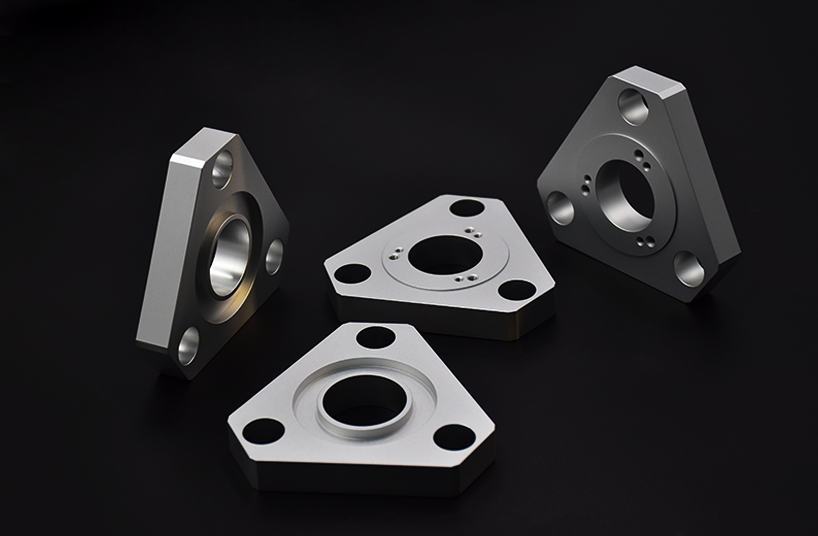

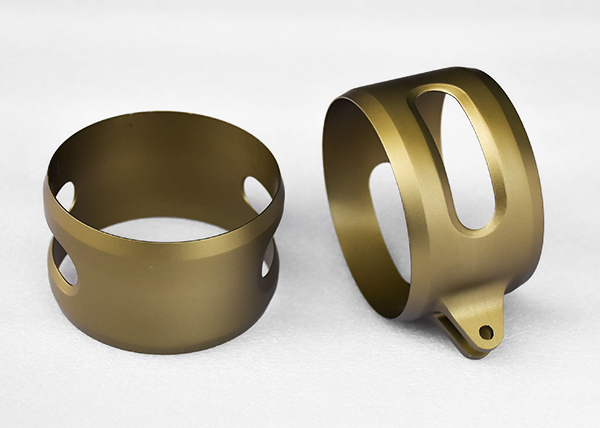

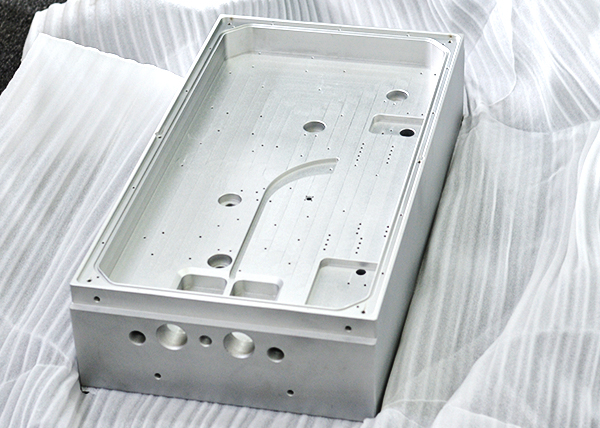

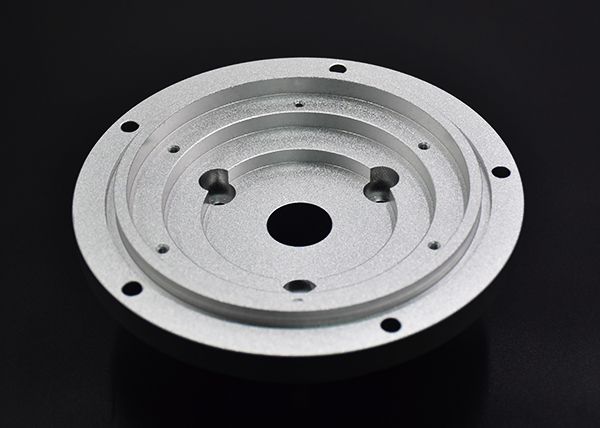

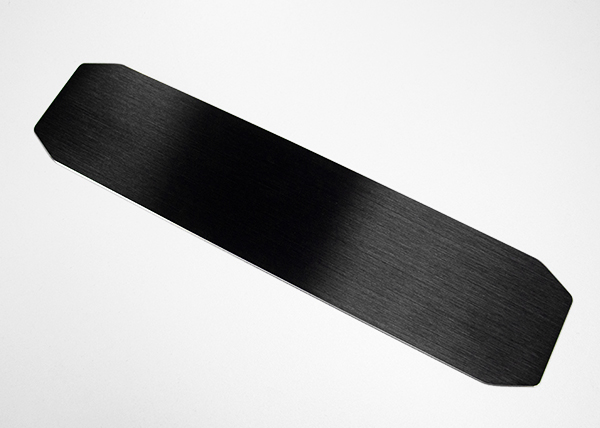

CNC Machined Parts Produced By SogaWorks

High-precision CNC machined prototypes and end-use parts that we have produced for our valued customers.

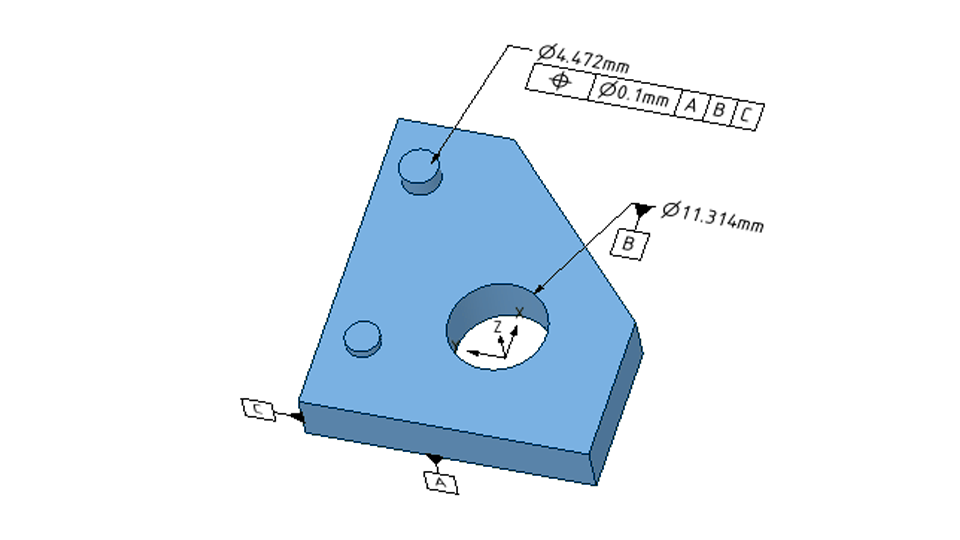

CNC Machining Tolerance

If not otherwise specified on the technical drawing, all parts will be machined to ISO 2768 tolerance standards below. Generally you can choose ISO 2768-m, ISO 2768-f or specify much tighter tolerances in your 2D technical drawings.

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

0.5mm to 3mm |

±0.1mm |

±0.05mm |

|

Over 3mm to 6mm |

±0.1mm |

±0.05mm |

|

Over 6mm to 30mm |

±0.2mm |

±0.1mm |

|

Over 30mm to 120mm |

±0.3mm |

±0.15mm |

|

Over 120mm to 400mm |

±0.5mm |

±0.2mm |

|

Over 400mm to 1000mm |

±0.8mm |

±0.3mm |

|

Over 1000mm to 2000mm |

±1.2mm |

±0.5mm |

|

Over 2000mm to 4000mm |

±2.0mm |

- |

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

Up to 10mm |

±1° |

±1° |

|

Over 10mm to 50mm |

±0°30′ |

±0°30′ |

|

Over 50mm to 120mm |

±0°20′ |

±0°20′ |

|

Over 120mm to 400mm |

±0°10′ |

±0°10′ |

|

Over 400mm |

±0°05′ |

±0°05′ |

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

0.5mm to 3mm |

±0.2mm |

±0.2mm |

|

Over 3mm to 6mm |

±0.5mm |

±0.5mm |

|

Over 6mm |

±1.0mm |

±1.0mm |

Roughness and threads

CNC Machining Materials

Many materials can be used in CNC machining technologies, which brings you a wide range of options for your CNC machined parts. At SogaWorks, we provide instant quotations on 40+ industrial-grade metal and plastic materials.

Aluminum

Aluminum alloys are a popular choice for CNC machining. They have good strength-to-weight ratio, excellent machinability and natural corrosion resistance.

– Aluminum 6061-T6

– Aluminum 7075-T6

– Aluminum 2024

– Aluminum 5052

– Aluminum 6063

– Aluminum 7050

– Aluminum MIC-6

Stainless Steel

A strong, hard metal with excellent corrosion resistance, easy to machine and weld, with stable mechanical properties in both high and low temperatures.

– Stainless Steel 303

– Stainless Steel 304

– Stainless Steel 304L

– Stainless Steel 316

– Stainless Steel 316L

– Stainless Steel 410

– Stainless Steel 430

– Stainless Steel 440C

– Stainless Steel 17-4PH

Steel Alloy

A high-strength, hard metal with excellent toughness and impact resistance, suitable for heavy-load applications. Easy to machine and weld, while prone to rust, its corrosion resistance can be improved with coatings.

– Steel Alloy 1045

– Steel Alloy 1215

– Steel Alloy 4130

– Steel Alloy 4140

– Steel Alloy 4340

– Steel Alloy 5140

– Steel Alloy A36

Brass

A medium-strength alloy with good wear and corrosion resistance, it is easy to machine, cast, and forge, with excellent fatigue resistance and damping properties.

– Brass C260

– Brass C274

– Brass C280

– Brass C360

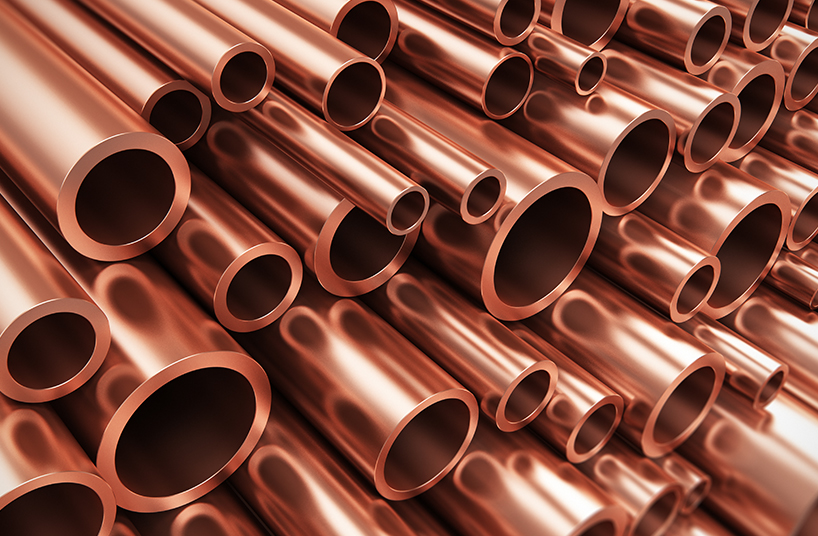

Copper

A highly conductive metal with excellent corrosion resistance, it is easy to machine, cast, and forge, and has good ductility and fatigue resistance.

– Copper C101

– Copper C102

– Copper C110

Titanium

A lightweight, high-strength metal with exceptional corrosion resistance. Though harder to machine, it has excellent fatigue resistance and high-temperature performance.

– Titanium Grade 5 6A1-4V

Plastics

In addition to metal materials, plastics are also important materials for CNC machining, Sogaworks offers multiple options of plastics, which include ABS, PC, PEEK, PMMA, and more.

– ABS

– HDPE

– LDPE

– Nylon

– PC

– PEEK

– PMMA (Acrylic) and more

* For materials not shown here, feel free to contact us directly.

Surface Finishes

Surface finishes are crucial for achieving the desired functional or aesthetic quality of CNC machined components. At SogaWorks, we offer a spectrum of surface finishes that enhance the aesthetics and functionality of your custom projects.

Grow a thickness oxide layer ranging from 0.0001 to 0.001 inches to protect and color aluminum CNC machined parts for corrosion resistance and aesthetics.

Create a thicker layer ranging from 0.001 to 0.004 inches. it is ideal for where hardness and wear resistance are crucial.

Anodizing Type III

Preserve or enhance the electrical conductivity of the aluminum parts while still providing the benefits of traditional type II.

Conductive Anodizing Type II

Cover a part with a thin layer of metal by electrochemical deposition for function, decoration or corrosion resistance.

Apply a protective coating of zinc to steel, iron, and copper objects to prevent corrosion.

Galvanizing

Apply a protective or functional coating to surfaces. It involves the application of liquid paint and then undergoes a curing process to solidify the paint film.

Painting

Apply a protective and decorative coating to materials, primarily metals. It involves applying a dry powder onto a surface, which is then applied electrostatically and cured under heat or UV light.

Spray silica sand onto the surface of the workpiece using compressed air to clean, smooth, or texture surfaces, providing a desired finish for functional or aesthetic purposes.

A conversion coating applied to ferrous metals to provide a thin, protective layer of black iron oxide.

Use abrasive belts or roller brushes to refine and improve the surface quality of components.

Selectively remove material from the surface, resulting in a smooth, polished, and often corrosion-resistant finish.

Manufacturing Capabilities and Equipment

- 30+ countries and regions

- 50,000+ customers

- 16,000,000+ parts manufactured in total

- 1,000+ collaborative partner factories

- 4,800+ precision equipment

Why Choose SogaWorks For CNC Machining Service

Quote in 5 Seconds

Offering a self-developed, machine learning-driven intelligent quoting platform, we can offer you fast and accurate CNC machining quotations in 5 seconds.

One-Stop Manufacturing Service

We provide one-stop manufacturing services from R&D prototypes to massive production. From bead blasting to polishing, anodizing to plating, we offer every surface finish you need to make a great finished part.

End-to-end Professional Service

Our specialized account managers and engineers provide “One to One” service, and work collaboratively with customers and by better understanding their requirements, which is to achieve better turnaround time and lower cost for your project

Fully Inspected Before Delivery

Before shipping out the parts to you, we conduct a strict final inspection for all parts with high-accuracy measuring equipment.

Serving Multiple Industries

Our rapid prototyping and on-demand production services are used across a wide range of industries, but the following areas are where we have the most experience.

Medical

Elevate the reliability of your medical devices with accurate manufacturing solution.

Aerospace

Lightweight and durable solutions for the most demanding aviation needs.

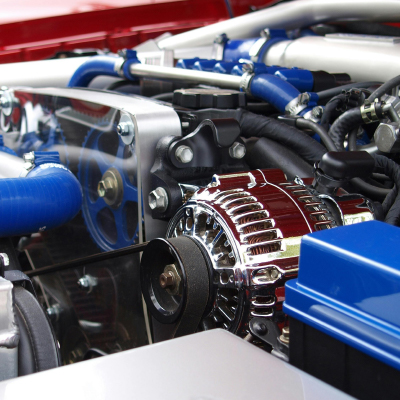

Automotive

Tailored to optimize performance and reliability in the automotive.

Robotics

Fuel your robotic innovations with our precision-engineered parts.

FAQs About CNC Machining Service

What is CNC machining?

CNC machining is a subtractive manufacturing process that typically uses a computer program to control cutting tools, remove layers of material from a workpiece, and produce custom-designed parts.

How much does CNC machining cost?

The expense associated with our CNC machining service is variable and directly influenced by the distinct attributes of your project, including its design and tolerance specifications. The machining duration for the chosen material is another key determinant of the cost.

Is there a MOQ for CNC machining?

We cater to both one-off prototype and large-scale production runs. Thus, there is typically no strict MOQ. Whether you need a single part or thousands, We aims to provide a solution.

How long does it take to obtain a part after an order is placed?

Lead times could change depending on the chosen material, the degree of design complexity. For smaller items specifically, CNC machining’s speed is one of its benefits. Machining times may be rather fast after the setup is finished. Parts delivered as fast as 2 day! For a more precise estimate, nevertheless, it is advisable to ask for quotations straight forwardly.