Electrical Discharge Machining (EDM) is one of the four most popular machining methods, alongside milling, turning, and grinding. Unlike traditional metal cutting, EDM uses electrical erosion from pulsed discharges between a tool electrode and a workpiece electrode to process materials. Sparks are visible during the discharge process, which is why it’s called electrical discharge machining.

Types of EDM

EDM processes vary and include EDM forming, wire EDM, EDM drilling, EDM grinding and boring, synchronous conjugate rotary EDM, surface strengthening, and engraving. The three most common types are: die sinking EDM, wire EDM, and hole drilling EDM.

Die sinking EDM

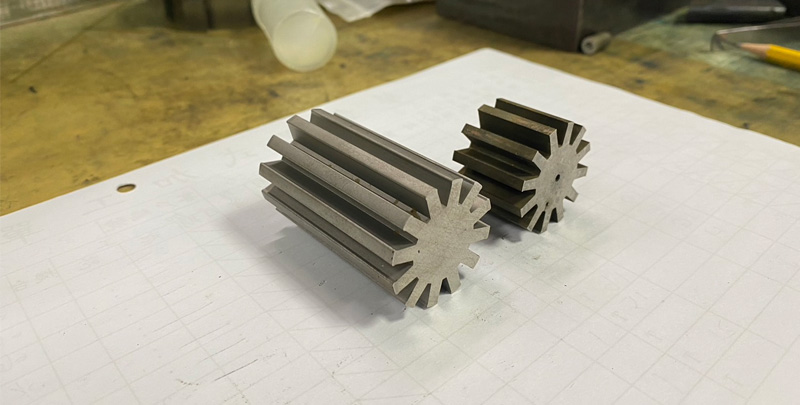

The tool electrode, typically made of copper or graphite, can be shaped into any desired form, producing a corresponding cavity in the workpiece.

Wire EDM

Wire EDM is categorized into two types: slow-speed and fast-speed wire cutting. It uses electrode wires (0.1mm to 0.3mm in diameter) to cut through parts with straight textures, such as punch or die hole components.

Hole Drilling EDM

Hole drilling EDM is used to create holes, especially small, deep ones that don’t require deburring. A pulsed cylindrical electrode is used, with dielectric fluid injected into the cutting area as the workpiece is penetrated.

EDM is widely used for machining high-melting-point, high-strength, and high-toughness materials like stainless steel and mold steel, as well as complex molds and parts with specific surface requirements.

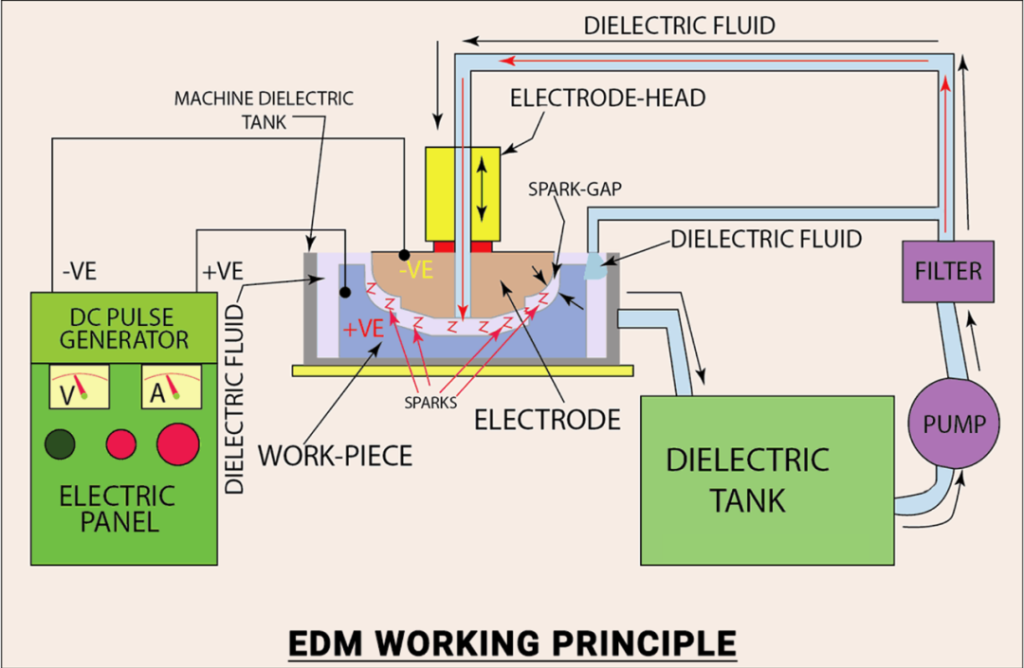

Principles of EDM

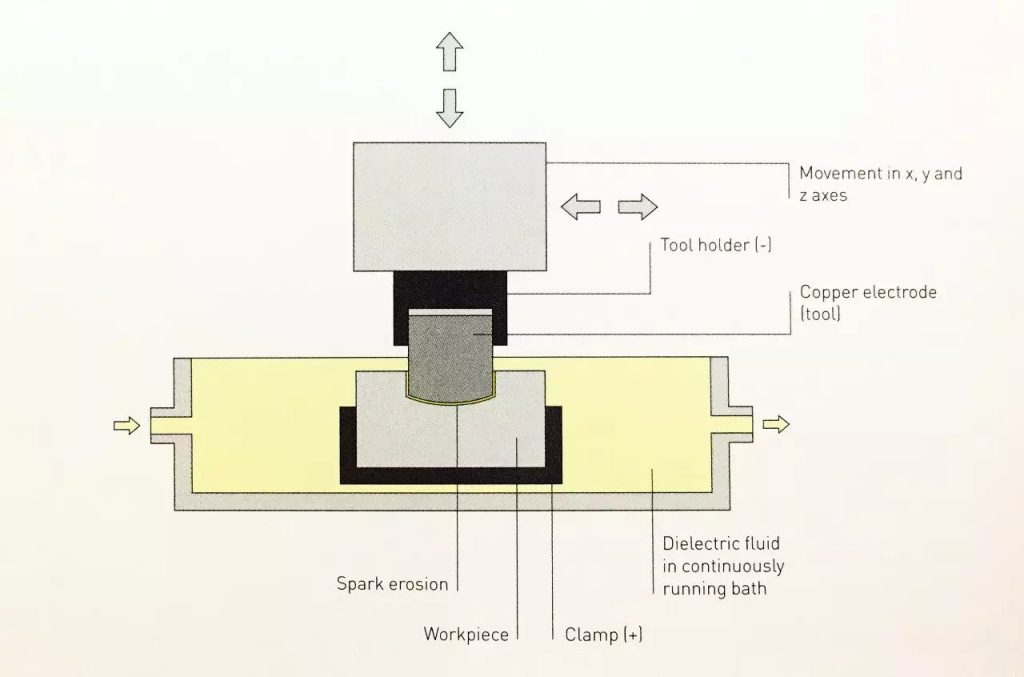

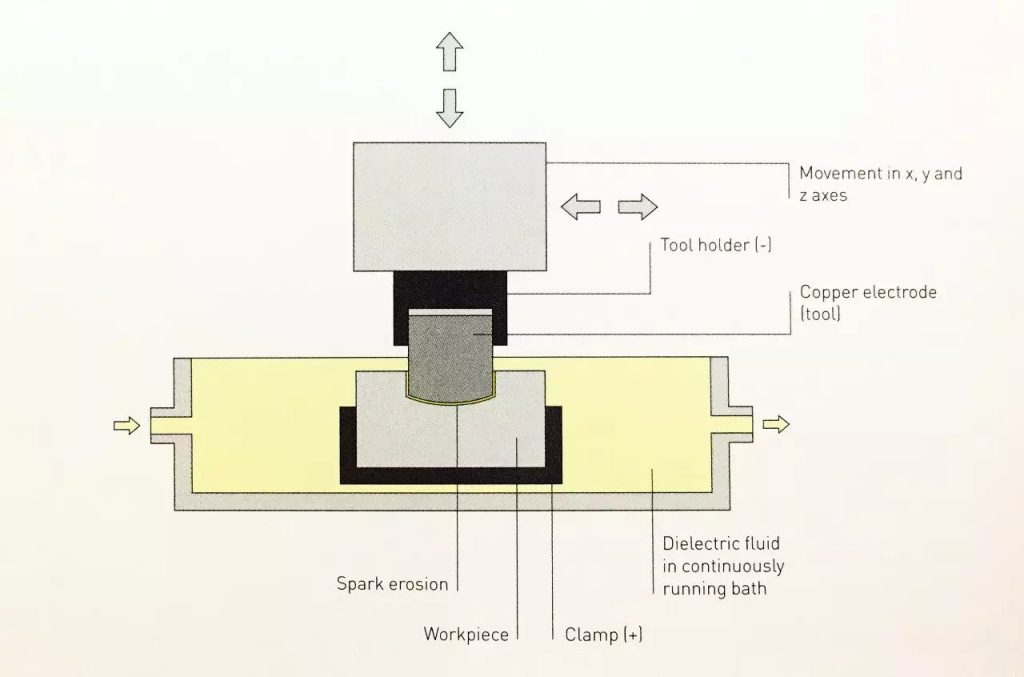

EDM relies on electrical erosion from pulsed spark discharges between the tool and workpiece (acting as positive and negative electrodes) to remove excess metal, achieving the desired dimensions, shapes, and surface quality.

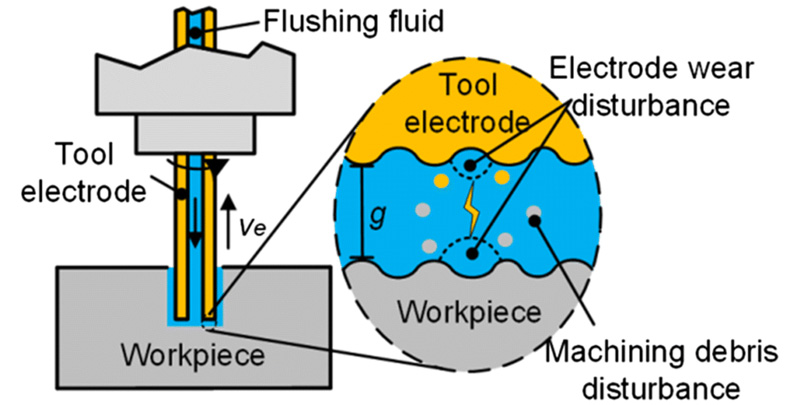

As shown in the diagram (not included here), the workpiece and tool electrode are connected to opposite poles of a pulsed power source. Tool electrodes are typically made from highly conductive, high-melting-point, erosion-resistant materials like copper, graphite, copper-tungsten alloy, or molybdenum. During machining, the tool electrode experiences some wear, but far less than the material removed from the workpiece, sometimes nearing negligible loss.

The working fluid serves as a discharge medium while also cooling and removing debris. Common fluids include low-viscosity, high-flash-point, stable media like kerosene, deionized water, or emulsions.

When a pulsed voltage is applied and an appropriate gap is maintained between the electrodes, the working fluid is broken down, forming a discharge channel. This channel generates instantaneous high temperatures, melting or vaporizing the workpiece surface material and the working fluid. The rapid thermal expansion in the discharge gap causes an explosion, ejecting a small amount of material and forming tiny erosion pits.

After each pulse, a brief interval allows the working fluid to regain its insulating properties. Repeated pulses continue this process, gradually eroding the workpiece material. A servo system adjusts the tool electrode’s position relative to the workpiece, ensuring consistent discharges until the desired part is produced.

Advantages of EDM

EDM uses electrical and thermal energy, not mechanical force, to remove metal, offering several advantages over traditional machining:

Machining Hard-to-Cut Materials: EDM excels at processing materials that are difficult to machine conventionally, showcasing a “soft overcoming hard” approach. Material removal depends on thermal properties (e.g., melting point, specific heat, thermal conductivity) rather than mechanical properties like hardness or toughness. Tool electrodes don’t need to be harder than the workpiece, making them easier to manufacture.

Complex and Special Shapes: Without relative cutting motion or cutting forces, EDM is ideal for low-rigidity workpieces and micro-machining. The short pulse discharge minimizes the heat-affected zone, making it suitable for heat-sensitive materials. The tool electrode’s shape can be easily replicated onto the workpiece, perfect for thin-walled, low-rigidity, elastic, micro, or complex surfaces like mold cavities.

Automation: EDM’s electrical parameters are easier to control digitally, enabling adaptive and intelligent control for rough, semi-finishing, and finishing stages. Once parameters are set, no manual intervention is needed.

Improved Structural Design: EDM allows for replacing assembled or welded structures with single-piece designs, improving reliability, reducing size and weight, and shortening mold production cycles.

Flexible Process Routes: Unaffected by material hardness, EDM can be performed after quenching, avoiding heat treatment deformation. For example, in die-casting or forging mold production, molds can be quenched to over 56HRC.

Limitations of EDM

Despite its advantages, EDM has certain limitations:

Limited to Conductive Materials: EDM is primarily used for metals and cannot process non-conductive materials like plastics or ceramics. Recent research, however, shows potential for machining semiconductors and polycrystalline diamond under specific conditions.

Low Machining Efficiency: EDM’s material removal rate is typically below 20mm³/(A·min), much lower than traditional machining. It’s often used after mechanical cutting removes most material. There’s also a trade-off between speed and surface quality—fine machining is slow, and rough machining is limited by surface quality.

Accuracy Constraints: Electrode wear during EDM, especially at sharp corners or bases, affects forming accuracy. While modern machines reduce relative electrode wear to below 1% for roughing and 0.1% for finishing, low-wear electrodes for fine machining remain a challenge.

Surface Imperfections: High instantaneous heat creates thermal stress, forming a heat-affected layer or micro-cracks on the workpiece surface.

Minimum Corner Radius: The smallest corner radius achievable is slightly larger than the discharge gap (typically 0.02–0.03mm). Electrode wear or orbital machining increases this radius, preventing perfectly sharp corners.

External Conditions: Discharges must occur in a working fluid to avoid abnormal sparking, which complicates monitoring and limits workpiece size.

Surface Finish: EDM surfaces consist of numerous discharge pits, lacking the “gloss” of mechanically machined surfaces. Polishing is required for a shiny finish.

Technical Expertise: EDM requires significant skill. Success depends on selecting appropriate methods, electrical parameters, electrode setup, positioning, process monitoring, and allowance determination. Experience is critical, especially with less automated equipment.

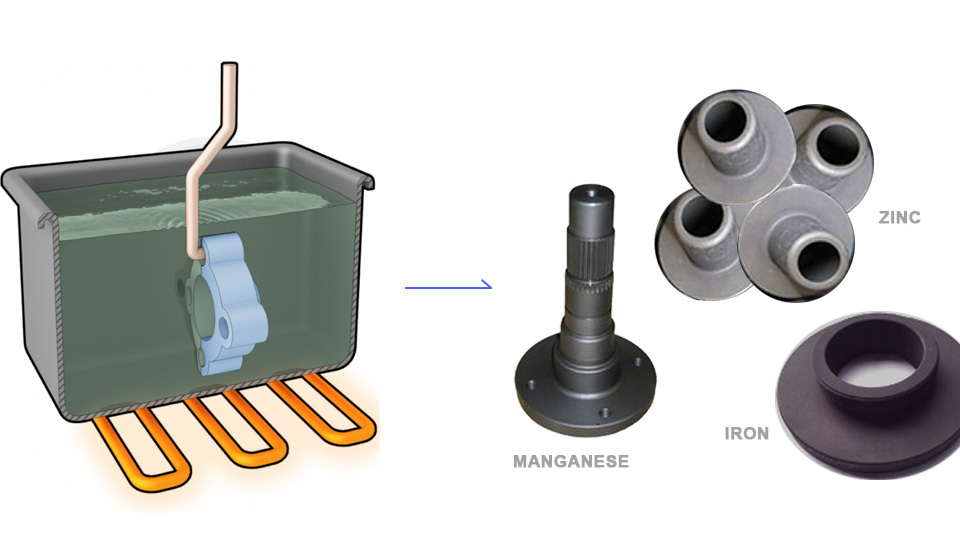

Materials EDM Work with

Nearly all conductive materials can be machined with electrical discharge machining. The following are the most common materials we work with:

- Aluminum

- Stainless steel

- Titanium

- Steel

- Brass/Copper/Bronze

Put Your Custom Parts into Production Today!

SogaWorks EDM Machining Capabilities

SogaWorks specializes in precision Electrical Discharge Machining (EDM) services. Our advanced EDM capabilities, including wire EDM and hole drilling EDM, enable us to machine materials like aluminum, stainless steel, and titanium with intricate shapes and tight tolerances to +/- 0.01 mm.

| Tolerance | +/- 0.01 mm |

| Lead time | < 10 days |

| Materials | Aluminum, stainless steel, steel, titanium and more |