In manufacturing, “standard parts” refer to components produced according to national or industry standards, offering interchangeability and universal application. In contrast, non-standard parts lack such universality and require customization based on specific product designs or manufacturing processes. According to a report by Allied Market Research, the global non-standard custom manufacturing market was valued at $858.8 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 4.6% from 2022 to 2031. This growth will drive increased demand for materials. Below, we outline the most commonly used materials in non-standard part custom manufacturing.

Q235A

Also known as A3 steel, Q235A is a common carbon steel with a carbon content below 0.22%. The “Q” stands for yield strength, “235” indicates a yield strength of 235 MPa, and “A” denotes its quality grade. It offers decent strength, good ductility, and toughness, capable of withstanding tensile, compressive, and bending loads. Q235A also has excellent weldability, minimizing defects like pores or cracks, and performs well in machining, cold bending, and hot bending.

| Tensile Strength (MPa): | 370–500 |

| Yield Strength (MPa): | 235 |

| Elongation at Break (%): | 26 |

| Density (g/cm³): | 7.86 |

45# Steel

This medium-carbon steel, with a carbon content of 0.42–0.50%, is equivalent to Japan’s JIS S45C standard. Widely used in non-standard designs, 45# steel offers excellent overall performance after tempering. It’s commonly used for gears, shafts, keys, and pins. For higher surface hardness, high-frequency quenching can be applied after tempering, achieving approximately 30 HRC after tempering and up to 45 HRC after quenching, meeting most operational requirements.

| Tensile Strength (MPa): | 600–800 |

| Yield Strength (MPa): | 355 |

| Elongation at Break (%): | 16 |

| Density (g/cm³): | 7.85 |

40Cr

When 45# steel’s properties fall short, 40Cr is a suitable alternative. This high-quality carbon structural steel, with 0.4% carbon and chromium alloying, significantly enhances performance after heat treatment. It achieves a hardness of about 35 HRC after tempering and nearly 60 HRC after high-frequency quenching, making it ideal for high-performance gears and shafts.

| Tensile Strength (MPa): | 810 |

| Yield Strength (MPa): | 785 |

| Elongation at Break (%): | 9 |

| Density (g/cm³): | 7.85 |

Stainless Steel 304

Containing 18% chromium and 8% nickel, also known as 18/8 stainless steel, 304 is non-magnetic in its annealed state and cannot be hardened through heat treatment. Cold working (e.g., stamping, stretching, bending, or rolling) may induce weak magnetism due to partial austenite-to-martensite transformation. It offers good resistance to atmospheric corrosion and oxidation.

| Tensile Strength (MPa): | 520 |

| Yield Strength (MPa): | 210 |

| Elongation at Break (%): | 40 |

| Density (g/cm³): | 7.93 |

Stainless Steel 316

An upgrade over 304, 316 stainless steel contains 18% chromium, 10% nickel (18/10), and added molybdenum for enhanced corrosion resistance, especially in harsh environments. It offers excellent work-hardening properties, high-temperature strength, and a glossy finish in cold-rolled products. It remains non-magnetic in its solution-treated state but is more expensive than 304.

| Tensile Strength (MPa): | 620 |

| Yield Strength (MPa): | 310 |

| Elongation at Break (%): | 30 |

| Density (g/cm³): | 7.98 |

CR12 Mold Steel

A high-carbon, high-chromium ledeburite steel, CR12 is a widely used cold-work mold steel. It offers good hardenability, wear resistance, and hot workability, with well-distributed carbides in the steel. It’s suitable for complex, heavy-duty cold-work molds.

| Tensile Strength (MPa): | 1770 |

| Yield Strength (MPa): | 1470 |

| Elongation at Break (%): | 5 |

| Density (g/cm³): | 7.7 |

SKD11

A high-carbon, high-chromium alloy tool steel, SKD11 offers excellent hardenability with minimal quenching distortion. After spheroidizing annealing, it provides good machinability, high hardness, wear resistance, and toughness, making it resistant to cracking.

| Tensile Strength (MPa): | 2260 |

| Yield Strength (MPa): | 1730 |

| Elongation at Break (%): | 3 |

| Density (g/cm³): | 7.85 |

65Mn

A high-manganese carbon spring steel, 65Mn has a carbon content of about 0.65% and manganese content of 0.9–1.2%. Manganese enhances hardenability, and its surface decarbonization is less pronounced than silicon steel. After heat treatment, it outperforms standard carbon steel but is prone to overheating sensitivity and temper brittleness.

| Tensile Strength (MPa): | 735 |

| Yield Strength (MPa): | 430 |

| Elongation at Break (%): | 14–21 |

| Density (g/cm³): | 7.85 |

Aluminum Alloy 6061

A heat-treatable alloy, 6061 offers good formability, weldability, and machinability while maintaining moderate strength post-annealing. Its dense, defect-free structure makes it easy to polish and coat, making it the top choice for anodizing among aluminum alloys.

| Tensile Strength (MPa): | 310 |

| Yield Strength (MPa): | 276 |

| Elongation at Break (%): | 12–17 |

| Density (g/cm³): | 2.7 |

Aluminum Alloy 7075

Known for high strength and good plasticity after solution treatment, 7075 excels in heat treatment and low-temperature strength. It’s widely used in aerospace, often called aviation aluminum, but has poor weldability and a tendency for stress corrosion cracking.

| Tensile Strength (MPa): | 572 |

| Yield Strength (MPa): | 504 |

| Elongation at Break (%): | 11 |

| Density (g/cm³): | 2.81 |

Brass, Copper, and Bronze

Brass: A copper-zinc alloy with strong wear resistance. H62 brass offers good mechanical properties, decent hot and cold plasticity, machinability, and weldability, but is prone to corrosion cracking. H65 provides high strength and plasticity, suitable for cold and hot pressure processing, though it may also crack under corrosion.

Copper: Pure copper has lower stiffness and hardness than brass but superior thermal and electrical conductivity, ideal for applications like laser welding tips requiring high conductivity.

Bronze: Alloyed with tin or lead, bronze offers good castability, wear resistance, and chemical stability, and is harder than pure iron.

Beryllium Bronze: Contains 1.7–2.5% beryllium plus small amounts of nickel and chromium. It boasts high strength, hardness, thermal/electrical conductivity, wear resistance, and corrosion resistance, but is costly.

PTFE (Teflon)

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance polymer with a wide temperature range (-180°C to 260°C) and an extremely low friction coefficient. One of the most corrosion-resistant materials, it resists all organic solvents but is soft, prone to deformation, and unsuitable for high-precision parts. It’s often used for wear-resistant components.

| Tensile Strength (MPa): | 23 |

| Elongation at Break (%): | 250 |

| Hardness (Shore D): | 50 |

| Melting Temperature (°C): | 327 |

| Density (g/cm³): | 2.2 |

Polyvinyl Chloride (PVC)

PVC is a versatile plastic with good chemical resistance, weatherability, and electrical insulation at a low cost. It’s widely used in pipes, cable insulation, construction, and packaging. Rigid PVC offers high strength, while soft PVC is flexible, but both have poor high-temperature resistance (up to 80°C) and release harmful gases when burned.

| Tensile Strength (MPa): | 45 |

| Elongation at Break (%): | 110 |

| Hardness (Shore D): | 80 |

| Heat Deflection Temperature (°C): | 72.5 |

| Density (g/cm³): | 1.3–1.45 |

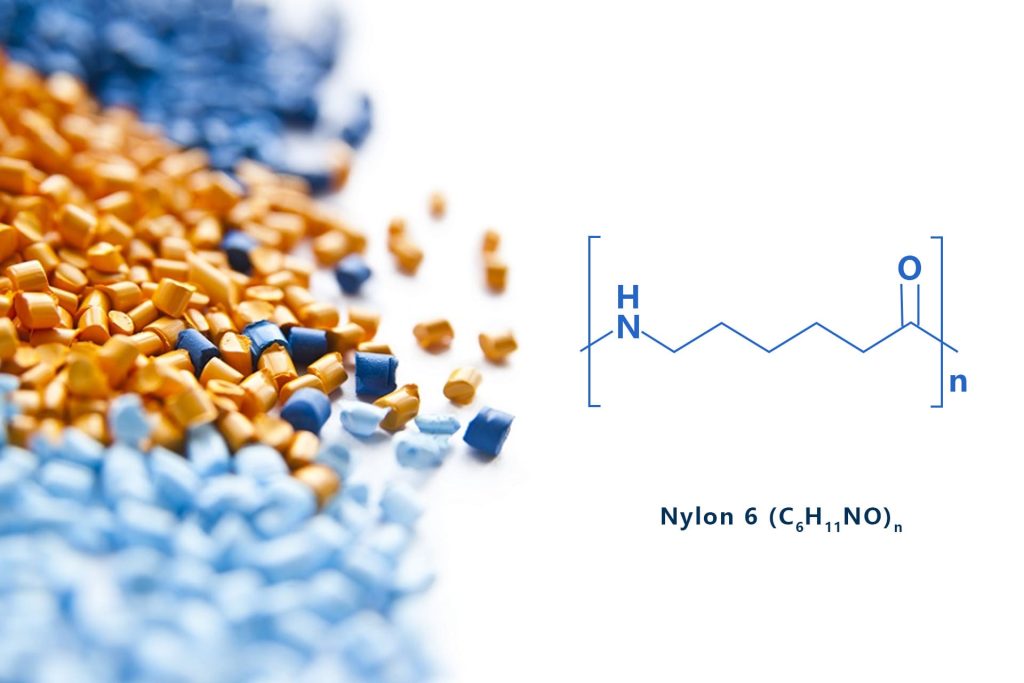

Nylon (PA, Polyamide)

Nylon is a high-strength, tough engineering plastic with excellent wear resistance, self-lubrication, and resistance to oil and chemicals. It’s used in gears, bearings, ropes, and textiles. However, its high water absorption affects dimensional stability and electrical properties, and it has moderate heat resistance (150–200°C). Common types include PA6 and PA66.

| Tensile Strength (MPa): | 30–98 |

| Elongation at Break (%): | 1–300 |

| Hardness (Shore D): | 75–85 |

| Heat Deflection Temperature (°C): | 75–428 |

| Density (g/cm³): | 1.12–1.15 |

Polyurethane (PU)

A versatile polymer, polyurethane can be made into elastomers, foams, or coatings. It offers excellent elasticity, wear resistance, oil resistance, and a wide hardness range (from soft rubber to hard plastic). It’s used in tires, seals, cushions, and hoses but has limited high-temperature resistance (up to 120°C) and poor resistance to strong acids and alkalis.

| Tensile Strength (MPa): | 20–50 |

| Elongation at Break (%): | 300–800 |

| Melting Temperature (°C): | 150–200 |

| Density (g/cm³): | 1.1–1.25 |

ABS

ABS is a general-purpose engineering plastic combining high strength, toughness, and good surface finish. It’s easy to process and plate, making it ideal for automotive parts, appliance housings, and toys like LEGO bricks. It has good impact resistance but limited heat resistance (up to 100°C) and poor resistance to strong acids, alkalis, and UV light.

| Tensile Strength (MPa): | 40 |

| Elongation at Break (%): | 50 |

| Hardness (Rockwell R): | 107 |

| Heat Deflection Temperature (°C): | 98 |

| Density (g/cm³): | 1.04–1.08 |

Polycarbonate (PC)

Polycarbonate is a highly transparent, impact-resistant engineering plastic with good heat resistance (120–140°C), electrical insulation, and dimensional stability. It’s used in bulletproof glass, optical lenses, safety helmets, and electronics housings. However, it has low surface hardness, is prone to scratches, and has moderate chemical resistance.

| Tensile Strength (MPa): | 40–154 |

| Elongation at Break (%): | 3–233 |

| Hardness (Shore D): | 90–95 |

| Heat Deflection Temperature (°C): | 57–208 |

| Density (g/cm³): | 1.2 |

Polypropylene (PP)

Polypropylene is a lightweight, cost-effective plastic with good chemical and fatigue resistance, commonly used in food containers, automotive parts, fibers, and pipes. It offers decent heat resistance (100–140°C) but becomes brittle at low temperatures and has moderate impact resistance and low surface hardness.

| Tensile Strength (MPa): | 19–45 |

| Elongation at Break (%): | 8–750 |

| Hardness (Shore D): | 45–80 |

| Heat Deflection Temperature (°C): | 60–130 |

| Density (g/cm³): | 0.90–0.91 |

Polyetheretherketone (PEEK)

PEEK is a high-performance engineering plastic with exceptional heat resistance (up to 250°C continuous use), mechanical strength, chemical resistance, and radiation resistance. It’s used in aerospace, medical implants, and precision mechanical parts but is expensive and difficult to process.

| Tensile Strength (MPa): | 90–100 |

| Elongation at Break (%): | 20–50 |

| Hardness (Shore D): | 85–90 |

| Melting Temperature (°C): | 343 |

| Density (g/cm³): | 1.3–1.32 |

Acrylic (PMMA)

Acrylic, or polymethyl methacrylate, is a highly transparent plastic with moderate hardness, good surface gloss, and strong weatherability. It’s used in optical lenses, billboards, lampshades, and display cases. It has poor impact resistance, is prone to breaking, and has limited heat (up to 90°C) and chemical resistance but is easy to cut and bond.

| Tensile Strength (MPa) | 5–120 |

| Elongation at Break (%) | 1–110 |

| Hardness (Shore D) | 62–90 |

| Heat Deflection Temperature (°C) | 182–210 |

| Density (g/cm³) | 1.18–1.19 |

About SogaWorks

SogaWorks is an all-in-one online platform for custom mechanical parts, connecting over 1,000 top-tier factories to serve startups and major companies. We offer flexible manufacturing solutions for rapid prototyping, small-volume testing, and large-scale production with services like CNC machining, 3D printing, urethane casting, and injection molding. Surface finishes include anodizing, sand blasting and phosphating. With our AI-powered quoting engine, SogaWorks can deliver quotes in 5 seconds, match the best capacity, and track every step. This cuts delivery times and boosts product quality.