The application of thread principles dates back to around 220 BCE, when the Greek scholar Archimedes created a spiral water-lifting tool. By the 4th century CE, Mediterranean countries began applying the principles of bolts and nuts in wine presses. At that time, external threads were made by wrapping a rope around a cylindrical rod and carving along the marked path, while internal threads were often formed by hammering softer materials around external threads.

Around 1500, Italian polymath Leonardo da Vinci sketched a thread-processing device that included concepts for using a lead screw and interchangeable gears to produce threads with different pitches. Subsequently, mechanical thread-cutting methods were developed in the European watchmaking industry. In 1760, British brothers J. Wyatt and W. Wyatt patented a specialized device for cutting wooden screws. In 1778, Englishman J. Ramsden built a thread-cutting device driven by a worm gear pair, capable of producing highly precise long threads. In 1797, Englishman H. Maudslay, using an improved lathe, employed a lead screw and interchangeable gears to turn metal threads with varying pitches, establishing the foundation for modern thread turning.

In the 1820s, Maudslay produced the first taps and dies for thread processing. In the early 20th century, the rise of the automotive industry drove thread standardization and the development of precise, efficient thread-processing methods. Automatic opening die heads and retractable taps were invented, and thread milling began to be used. In the early 1930s, thread grinding emerged. Although thread rolling technology was patented in the early 19th century, its development was slow due to challenges in manufacturing molds. It wasn’t until World War II (1942–1945), when advancements in thread grinding solved mold precision issues, that thread rolling saw rapid progress due to the demands of munitions production.

Threads are primarily divided into connecting threads and transmission threads. For connecting threads, the main processing methods include tapping, threading, turning, rolling, and rubbing. For transmission threads, the primary methods are rough and finish turning followed by grinding, or cyclone milling followed by rough and finish turning.

Category 1: Thread Cutting

Thread cutting generally refers to processing threads on a workpiece using forming tools or grinding equipment. These include turning, milling, tapping, threading, grinding and lapping. During turning, milling, or grinding, the machine’s transmission chain ensures that the tool (turning tool, milling cutter, or grinding wheel) moves accurately and uniformly along the workpiece’s axis by one lead per revolution. In tapping or threading, the tool (tap or die) rotates relative to the workpiece, guided by pre-formed thread grooves to move axially.

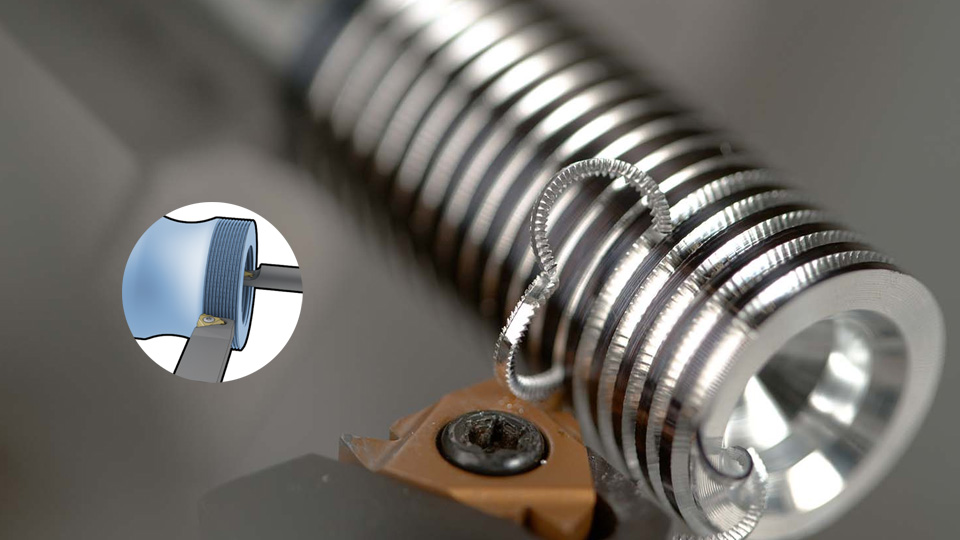

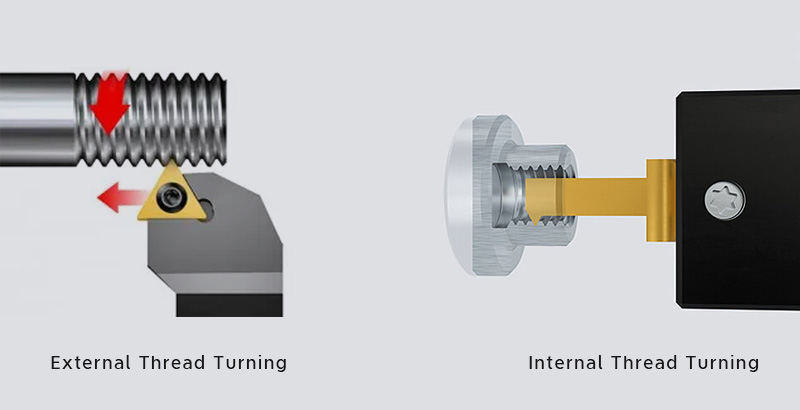

1. Thread Turning

Thread turning on a lathe can be done using a forming tool or a thread comb tool. Turning with a forming tool is commonly used for single-piece or small-batch thread production due to its simple structure. Thread comb tools offer high efficiency but more complex structures, which makes them suitable for medium to large-volume production of short, fine-pitch threads. Ordinary lathes typically achieve a pitch accuracy of Grade 8–9 (per JB2886-81 standard); Specialized thread lathes significantly improve productivity or precision.

2. Thread Milling

Thread milling is performed on a thread milling machine using a disc-shaped or comb-shaped milling cutter. Disc-shaped cutters are primarily used for milling trapezoidal external threads on screws or worm gears. Comb-shaped cutters are used for milling internal and external standard threads. Since multi-edge cutters are used and their working length exceeds the thread length, the workpiece only needs to rotate 1.25–1.5 times to complete processing, which offers higher productivity. Thread milling typically achieves a pitch accuracy of Grade 8–9 and a surface roughness of 5–0.63 microns. This method is ideal for batch production of general-precision threads or roughing before grinding.

3. Thread Grinding

Thread grinding uses thread grinding machines to process precision threads on hardened workpieces. It is divided into single-line and multi-line grinding based on the cross-sectional shape of the grinding wheel. Single-line grinding achieves a pitch accuracy of Grade 5–6 with a surface roughness of 1.25–0.08 microns. This method is suitable for grinding precision screws, thread gauges, worms, small-batch threaded workpieces, and precision hobs. Multi-line grinding is further divided into longitudinal and plunge grinding. In longitudinal grinding, the wheel width is less than the thread length, and the wheel moves longitudinally once or several times to achieve the final dimensions. In plunge grinding, the wheel width exceeds the thread length, and the wheel cuts radially into the workpiece. Plunge grinding offers higher productivity but slightly lower precision. It’s suitable for grinding large batches of taps or certain fastening threads.

4. Thread Lapping

Thread lapping uses softer materials like cast iron to make nut- or screw-shaped lapping tools. These tools rotate in both directions to correct pitch errors in pre-machined threads, improving accuracy. Hardened internal threads are often lapped to eliminate deformation and enhance precision.

5. Tapping and Threading

Tapping: Rotating a tap with a specific torque into a pre-drilled hole to create internal threads.

Threading: Uses a die to cut external threads on a rod or tube. The accuracy depends on the precision of the tap or die. Although there are many methods for making internal and external threads, small-diameter internal threads can only be produced by tapping. Tapping and threading can be done manually or using lathes, drilling machines, tapping machines, or threading machines.

Category 2: Thread Rolling

Thread rolling uses forming molds to plastically deform a workpiece to create threads. It is typically performed on rolling or rubbing machines or automatic lathes with self-opening thread rolling heads. This method is ideal for mass-producing standard fasteners and other threaded components. Rolled external threads generally have a maximum diameter of 25 mm and a length of up to 100 mm, with a thread accuracy of up to Grade 2 (GB197-63). The blank diameter is roughly equal to the thread’s pitch diameter. Rolling cannot typically produce internal threads, but for softer materials, slotless extrusion taps can cold-form internal threads up to about 30 mm in diameter, with a working principle similar to tapping. Cold-forming internal threads requires about twice the torque of tapping, with slightly higher precision and surface quality.

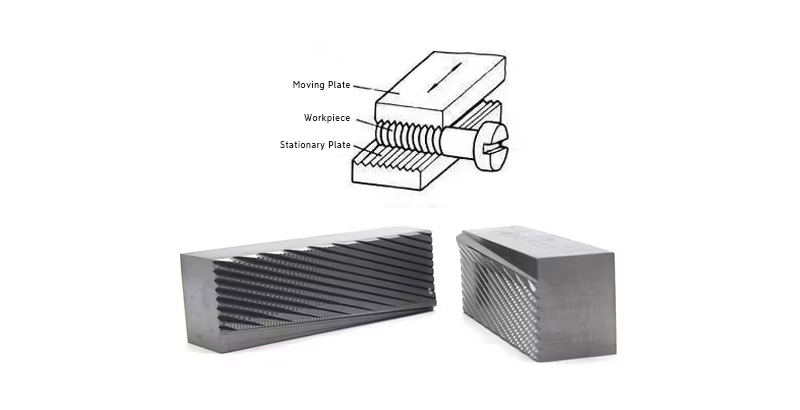

6. Rubbing

Two thread-forming rubbing plates, offset by half a pitch, are arranged with one plate fixed and the other moving linearly parallel to it. When a workpiece is fed between the plates, the moving plate presses and deforms the workpiece surface to form threads.

7. Rolling

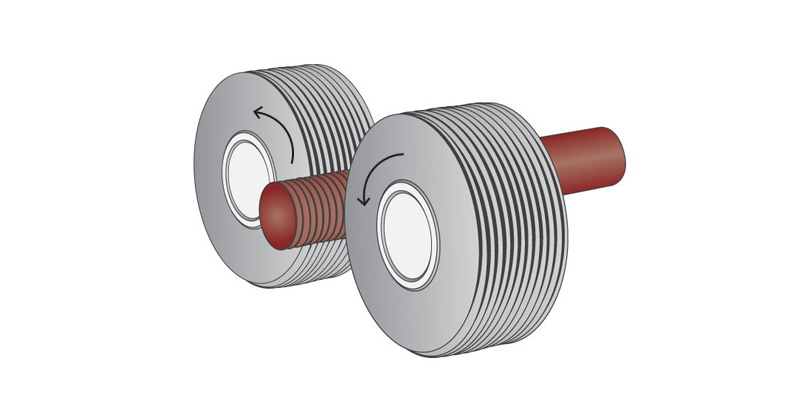

Rolling is divided into radial, tangential, and rolling head methods:

Radial Rolling: Two (or three) thread-forming rolling wheels are mounted on parallel axes, with the workpiece supported between them. Both wheels rotate in the same direction at the same speed, with one wheel also feeding radially. The workpiece rotates under the wheels’ drive, and the surface is radially pressed to form threads. This method can also be used for rolling low-precision screws.

Tangential Rolling (Planetary Rolling): The rolling tool consists of a rotating central wheel and three fixed arc-shaped plates. Workpieces are continuously fed, offering higher productivity than rubbing or radial rolling.

Rolling Head Rolling: Performed on automatic lathes for short threads. The rolling head has 3–4 rolling wheels evenly distributed around the workpiece. During rolling, the workpiece rotates, and the rolling head feeds axially to form threads.

8. Electrical Discharge Machining (EDM) for Threads

Standard thread processing typically utilizes machining centers or tapping tools, which may be performed manually. However, in specific cases, such as threading after heat treatment due to oversight or threading hard materials like cemented carbide, conventional methods may not yield good results. In such cases, EDM is a viable option.

Compared to mechanical machining, EDM follows a similar sequence, requiring a pre-drilled hole with a diameter determined by the working conditions. The electrode must be shaped like a thread and rotated during processing.

About SogaWorks

SogaWorks is an all-in-one online platform for custom mechanical parts, connecting over 1,000 top-tier factories to serve startups and major companies. We offer flexible manufacturing solutions for rapid prototyping, small-volume testing, and large-scale production with services like CNC machining, 3D printing, urethane casting, and injection molding. With our AI-powered quoting engine, SogaWorks can deliver quotes in 5 seconds, match the best capacity, and track every step. This cuts delivery times and boosts product quality.