Passivation Service

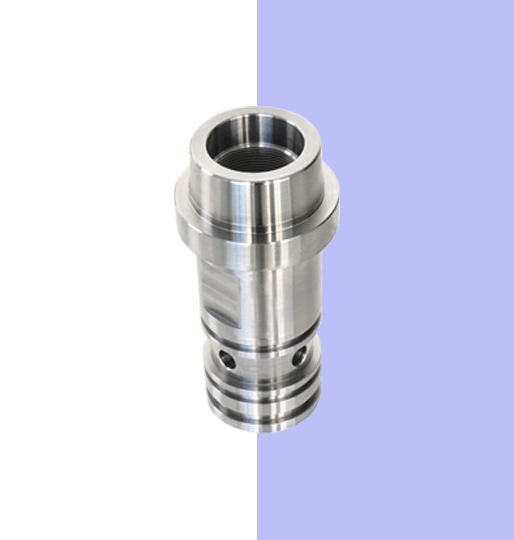

Our passivation services can provide excellent surface finishes for metal parts with intricate features and complex geometry.

Passivation Specification

Passivation is a process of treating the surface of metals with acid solutions, usually to remove free iron and other contaminants, to enhance the corrosion resistance of the metals. The common application of this process is on stainless steel, copper, and brass to form a protective oxide layer.

Materials |

Cosmetic Availability |

Visual Appearance |

Stainless Steel, Copper, Brass |

N/A |

Smooth glossy finish |

|---|

Advantages

- Reduced susceptibility to corrosion resistance.

- Removes surface contaminants and impurities, which improves part’s cleanliness.

- It prevents discoloration, staining, or rust formation of the stainless-steel part.

Notes

- The composition of the alloy influences the efficiency of passivation.

- Passivation is most effective on stainless steel and copper, other metals may not achieve the same level of corrosion resistance.

Passivation Finish

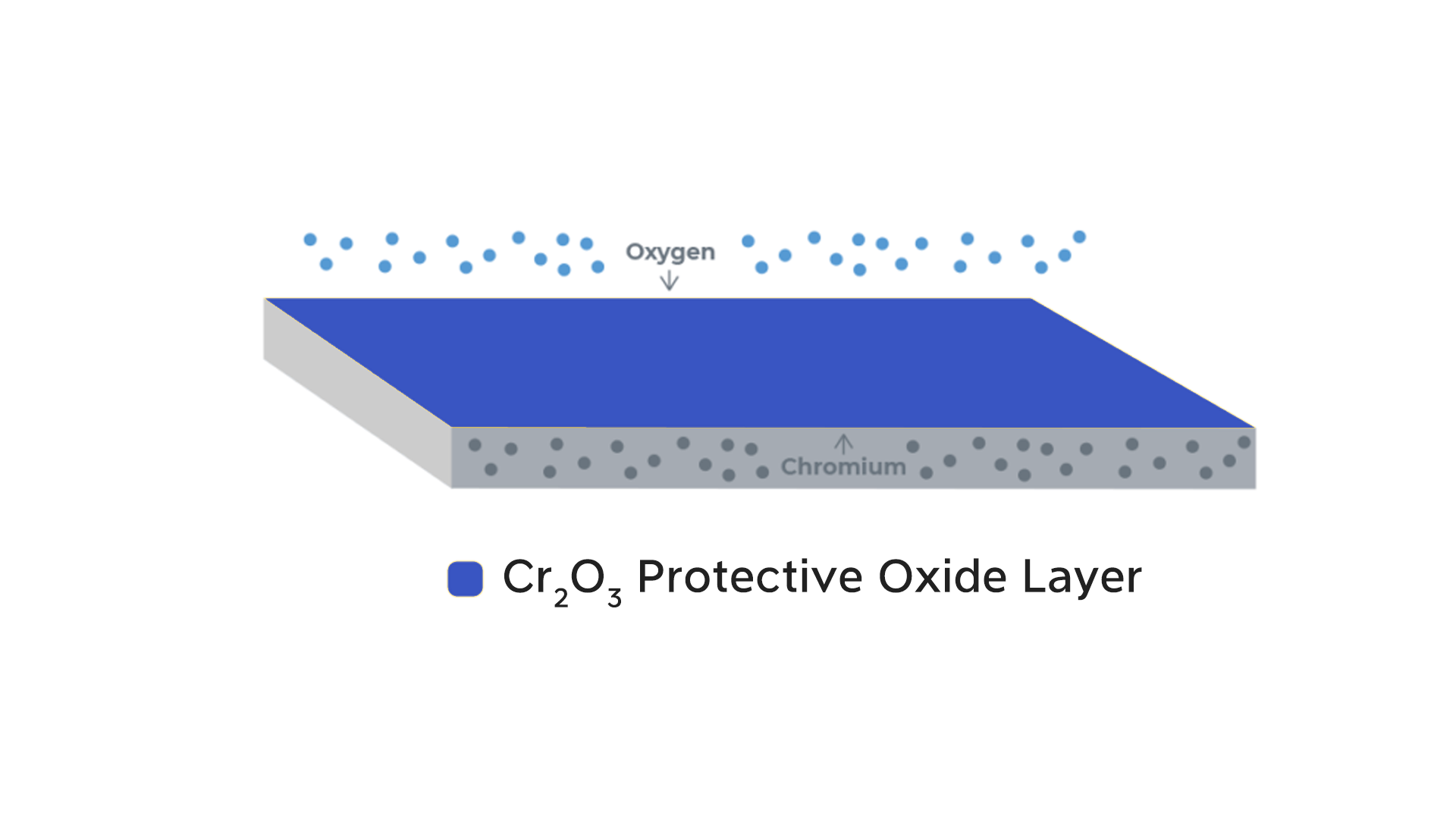

Passivation is an electrochemical process that enhances the resistance of metals, mainly stainless steel and copper, against the effects of corrosion by building a protective oxide layer over their surface.

This process involves cleaning the metal to remove impurities and then treating the cleaned metal in an acid solution, usually nitric or citric acid, in order to dissolve free iron and other contaminants. This removes the alloying elements, like chromium in stainless steel, which react with oxygen to form a thin stable oxide layer that acts like a barrier, preventing further corrosion; hence, resistance to environmental factors.

- The success of passivation depends on the initial condition of the surface. Ensure that the metal surfaces are free from contaminants, scale, and oxides before initiating the passivation process.

- Choose the proper acid bath that matches your intended application’s specific alloys.

- Ensure that the passivation chemical treatment is uniform throughout the metal surface.