Common Materials in Non-standard Custom Manufaturing

In this article, we have listed 20 types of common materials in non-standard part custom manufacturing.

In this article, we have listed 20 types of common materials in non-standard part custom manufacturing.

Polyetheretherketone (PEEK), developed by Imperial Chemical Industries (ICI) in 1978, is a semi-crystalline, linear aromatic polymer composed of alternating ether bonds, aromatic rings, and carbonyl groups. This thermoplastic, ultra-high-performance engineering plastic boasts a molecular structure with numerous benzene rings, where the relatively flexible C-O bonds are effectively protected by the steric hindrance of two benzene

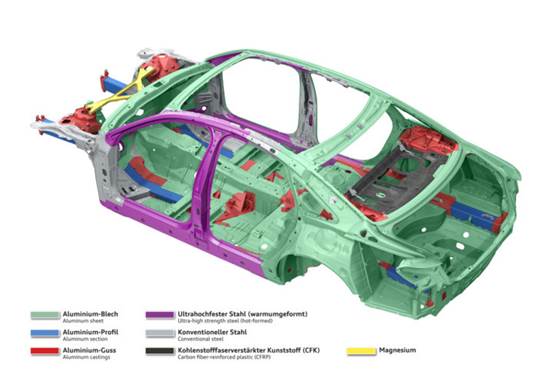

With technological advancements and growing market demand, aluminum usage in small to mid-sized vehicles has increased.

Aluminum is a soft, lightweight metal. The density of aluminum alloy depends on its alloying elements.

This article will introduce you to 9 basic mechanical properties of materials: strength, plasticity, hardness, toughness, fatigue, elasticity, stiffness, wear resistance, and corrosion resistance.

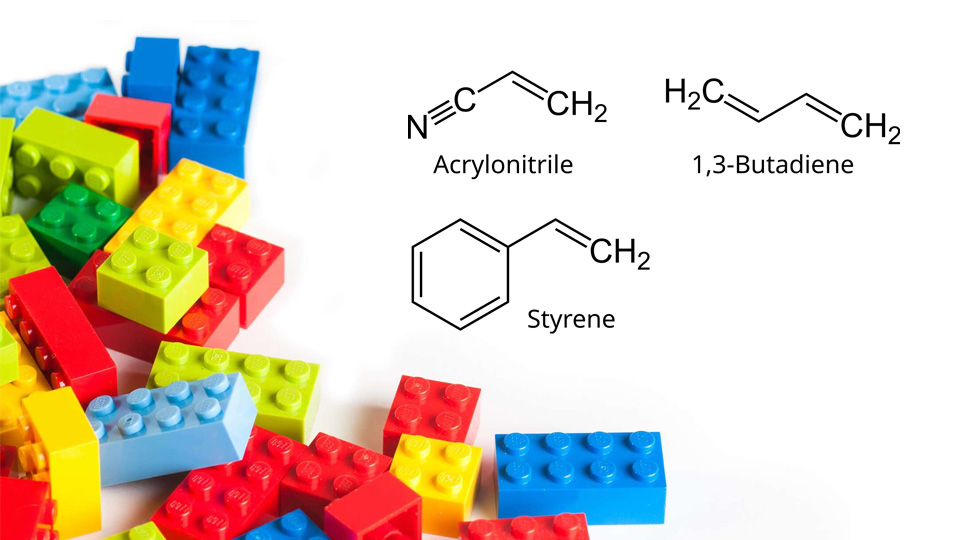

Acrylonitrile Butadiene Styrene (ABS) resin has balanced properties such as high strength, toughness, and versatility. This article will discuss its fundamental properties, classifications, performance characteristics, and processing techniques. What is ABS Plastic? ABS resin is a ternary copolymer composed of acrylonitrile (A), butadiene (B), and styrene (S), along with its modified variants. Plastics made from

We will provide a comprehensive overview of the major properties of brass to help readers understand this essential engineering material.

How much does titanium cost per pound? In this blog, we will organize the current market price of titanium and analyze the various factors that affect it.

Steel is an alloy made by blending different base metals with certain alloying elements. There are numerous types of stainless steels with different properties, but they all have one thing in common: the addition of chromium, which imparts corrosion resistance. One of the most recognizable types of stainless steel, 304 stainless steel, is widely used

Address:

Room 101-117(the entire 1st floor), 2nd Building,

Tianxin Industrial Zone, Guxing Community, Xi’xiang Street,

Bao’an District, Shenzhen, China. 518126