Phosphating is a process that forms a phosphate conversion coating on a metal surface through chemical and electrochemical reactions. This coating offers excellent adhesion, corrosion resistance, and enhances the durability and bonding strength of subsequent coatings. Phosphating is widely used for surface treatment of metals like steel, zinc, and aluminum, particularly in industries such as automotive, appliances, and construction.

History of Phosphating

Phosphating has a long history and is one of the earliest surface treatment techniques in modern metal processing. Its development has gone through several stages.

In 1869, the discovery of phosphate coatings in the UK showed that they could effectively protect metals from corrosion over extended periods. This led to the first patent for phosphating, laying the foundation for its technological advancement.

From the early 20th century, phosphating began to be applied to industrial products, driving further development and entering a phase of practical application.

Now, phosphating processes have evolved to meet diverse needs, focusing on low-temperature processing, reduced residue, and environmentally friendly, non-toxic formulations.

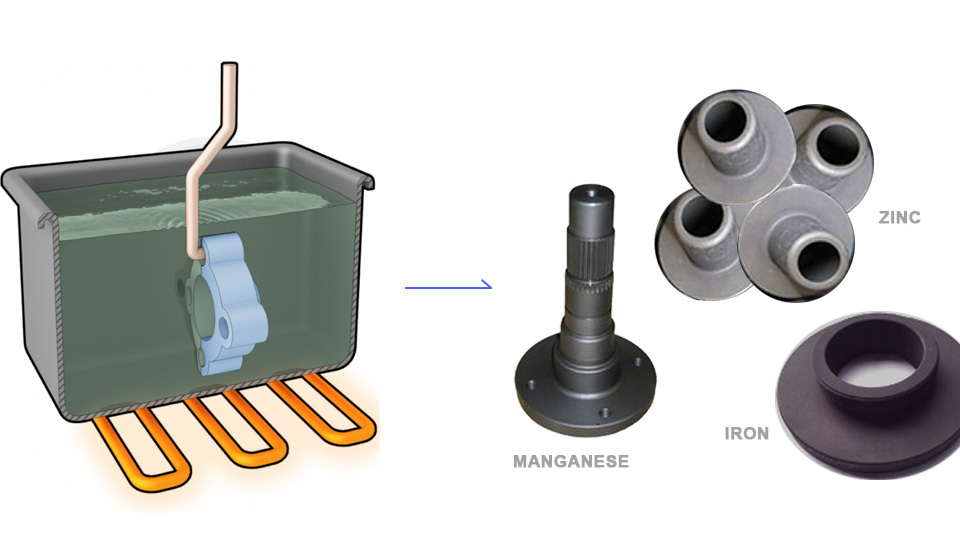

Types of Phosphating

Unlike most surface treatments that result in a single color, phosphating can produce various colors—gray, iridescent, or black—depending on the phosphating agent used.

Iron Phosphating

This process creates a rainbow-like or blue coating, often called color phosphating. The phosphating solution, primarily composed of molybdate, forms a rainbow-colored film on steel surfaces. It is mainly used as a base layer for coatings to enhance corrosion resistance and improve adhesion of the topcoat.

Zinc Phosphating

This produces a gray coating, known as gray film phosphating. The solution typically contains phosphoric acid, sodium fluoride, and emulsifiers, forming a gray phosphate film on the metal surface. It serves as a base for processes like powder coating, painting, or electrophoresis. The gray film also provides some corrosion resistance and can be used alone as a protective coating on surfaces like galvanized steel, cold-rolled steel, or aluminum.

Manganese Phosphating

This results in a black or dark gray coating, often called black phosphating. Using a manganese-ion-containing solution, it forms a black phosphate film with superior rust resistance, making it ideal for long-term corrosion protection. Its low friction coefficient makes it suitable for components subject to frequent friction, such as automotive parts and fasteners.

Principles of Phosphating

Phosphating works by triggering a chemical reaction between active sites on the metal surface and phosphate ions in the solution, forming a dense phosphate conversion coating. During this process, impurities like oil and rust are removed, exposing more active sites to facilitate the reaction.

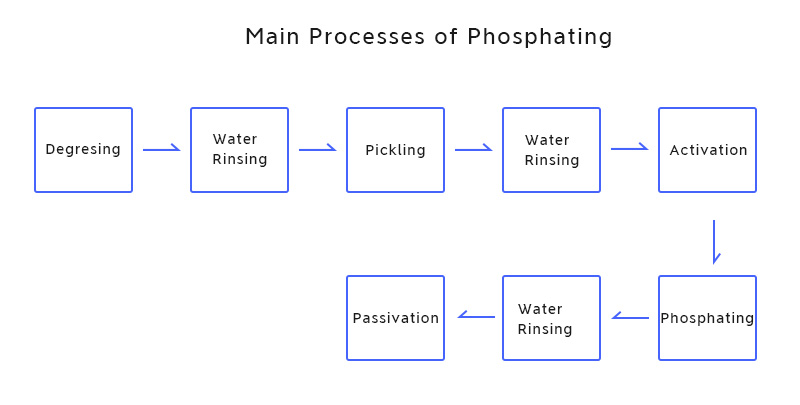

Steps in the Phosphating Process

Phosphating typically involves the following steps:

Pre-treatment: Removes oil, rust, and oxide scales to provide a clean surface for the phosphating reaction.

Phosphating Reaction: The metal is immersed in a phosphating solution, where a chemical reaction forms a phosphate conversion coating. The solution’s formula and process parameters significantly affect the coating’s quality and performance.

Post-treatment: Includes rinsing, drying, and passivation to remove residual chemicals and enhance the coating’s corrosion resistance and durability. Each step is followed by rinsing to remove residual chemicals, ensuring the next step proceeds smoothly. After phosphating and rinsing, the workpiece is dried to complete the process, ready for further processing or use.

Phosphating is a simple and practical method for corrosion protection in modern metal surface treatments. It plays a critical role as a pre-treatment step and has significantly advanced the surface coating industry. However, challenges remain, driving improvements toward energy efficiency, environmental friendliness, non-toxicity, and higher efficiency.

Why Does Phosphating Produce Multiple Colors?

The ability of phosphating to produce various colors depends on factors like the coating formation mechanism, phosphating solution formula, process parameters, and post-treatment. Below, we explore these in detail.

Coating Formation Mechanism

The phosphate coating forms through a chemical reaction between active sites on the metal surface and phosphate ions in the solution. Different metals and phosphate ions produce distinct chemical combinations, resulting in coatings with varying colors and properties. For example, iron phosphate films typically appear gray-black, while zinc phosphate films may be light yellow or gray.

Phosphating Solution

The solution’s composition significantly influences the coating’s color and performance. Typically containing phosphates, additives, and auxiliaries, the solution’s phosphate type and concentration alter the coating’s composition and structure, affecting its color. Additives like organic dyes or inorganic pigments can also be included to produce specific colors.

Process Parameters

Parameters like temperature, time, and pH affect the reaction rate and extent, influencing the coating’s composition and structure. For instance, higher temperatures can accelerate the reaction, creating a denser, more uniform coating, while longer processing times result in thicker, more robust coatings. These changes impact the coating’s color and performance.

Post-Treatment

Post-treatments like rinsing, drying, and passivation can alter the coating’s surface state and chemical properties, affecting its color and performance. For example, different passivating agents can modify the coating’s color and corrosion resistance during passivation.

Conclusion

With advancements in technology and industry, phosphating is increasingly vital in metal surface treatments. Future developments will focus on efficiency, environmental sustainability, and multifunctionality. Optimizing solution formulas and process parameters can produce more uniform and dense coatings, while eco-friendly phosphating agents and additives will reduce pollution and waste. Additionally, combining phosphating with other surface treatments, like spraying or electroplating, can further enhance metal surface performance and aesthetics.

About SogaWorks

SogaWorks is an all-in-one online platform for custom mechanical parts, connecting over 1,000 top-tier factories to serve startups and major companies. We offer flexible manufacturing solutions for rapid prototyping, small-volume testing, and large-scale production with services like CNC machining, 3D printing, urethane casting, and injection molding. Surface finishes include anodizing, sand blasting and phosphating. With our AI-powered quoting engine, SogaWorks can deliver quotes in 5 seconds, match the best capacity, and track every step. This cuts delivery times and boosts product quality.