Brass is a popular alloy material in everyday production because it possesses better mechanical properties, corrosion resistance, and formability. Brass, composed mainly of copper and zinc, can be engineered by varying its composition to achieve various physical and chemical properties. Here in this paper, we will give a comprehensive overview of the most important properties of brass, such as strength, electrical and thermal conductivity, and corrosion resistance so that you readers are able to study this important engineering material.

What is Brass?

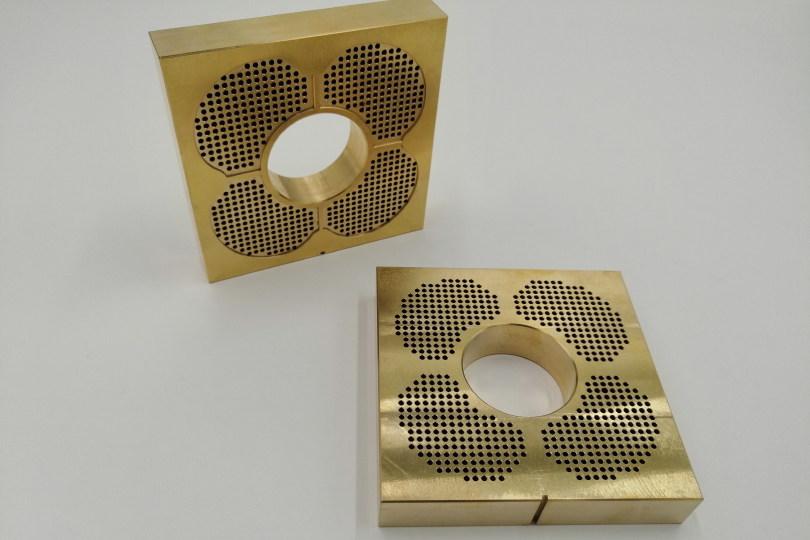

Brass is a go-to metal alloy in manufacturing, It is made mostly of copper and zinc, the metal is favored by designers for its easy machining, solid corrosion resistance, and sharp, polished look. Brass comes together by carefully melting copper and zinc in just the right mix, usually 55-95% copper and 5-45% zinc, depending on what properties you’re aiming for. The manufacturing process of brass starts with melting the copper in a furnace to about 1,050°C until molten and then adding zinc, which has a melting point much lower at about 420°C. The two are well mixed to get an even mixture, sometimes with a pinch of lead or tin to add such qualities as machinability or hardness. Once it is all mixed, we pour the mixture into ingots or billets using molds, let it cool, and get it ready for rolling, extruding, or machining.

Color of Brass

The bright yellow to gold-like appearance of brass is both a matter of aesthetics as well as practicality.

This color is also determined by the precise ratio of copper to zinc in the alloy, the higher copper content yields a reddish color in brass, and higher zinc content yields a paler, more silvery-yellow color. During manufacturing, processes such as casting, extruding, or machining expose new surfaces of the alloy and demonstrate its intrinsic metal luster. Further surface treatment, such as polishing or buffing, brightens it and darkens its golden color.

Common Brass Grades Used for Machining

There are several common brass grades utilized in machining, and the most prevalent grades are C26000, C27400, C28000, and C36000, with each having different composition and properties and being well-suited for specific machining applications.

Brass C26000

C26000, or cartridge brass, contains roughly 70% copper and 30% zinc and offers an excellent blend of ductility, corrosion resistance, and strength, particularly in wet environments. Its formability makes it suitable for cold working and machining into products like ammunition casings, auto radiator cores, and hardware trim, though its machinability is only fair compared to leaded brass.

Brass C27400

C27400, or yellow brass, contains about 63% copper and 37% zinc, with excellent machinability and economy due to its increased percentage of zinc, reducing the cost of material. It is suitable for plumbing fittings, tubing, and low-cost hardware where moderate strength and satisfactory corrosion resistance are desired.

Brass C28000

C28000, which is also referred to as Muntz metal, has around 60% copper and 40% zinc content, and it offers more strength and better corrosion resistance when working in marine conditions. It has good machinability and is used in architectural panels, marine hardware, and structural components where toughness is needed.

Brass C36000

C36000 or free-cutting brass contains 61.5% copper, 35.5% zinc, and 2-3% lead, significantly enhancing its machinability, for which it is employed in high-speed machining. The presence of lead in it requires special handling for compliance with regulatory standards. Choosing the grade to be machined on CNC is a compromise between strength, machinability, corrosion resistance, and application-specific requirements for optimal performance and economy.

World Equivalents of Brass Alloys

The following table shows the equivalents for common brass grades:

| US-UNS | CN-GB | UK-BSI | DE-ISO | JP- JIS |

| C26000 | H68 | CZ106 | CuZn30 | C2600 |

| C27400 | H62 | CZ109 | CuZn40 | C2720 |

| C28000 | H59 | CZ109 | CuZn40 | C2800 |

| C36000 | HPb62-3 | CZ124 | CuZn36Pb3 | C3601 |

Mechanical Properties of Brass Alloys

The standard grades C26000, C27400, C28000, and C36000 each have their composition and properties that make them suitable for specific machining applications. The following is an in-depth examination of their mechanical properties.

Tensile Strength: 338 to 469 MPa

Typical brass alloys have tensile strengths of between 338 and 469 MPa, varying with temper (for example, annealed or half-hard) and alloy composition. This suggests that these alloys will resist significant pulling or stretching forces before failure. In machining applications where components are exposed to intermittent or repeated tensile forces, such as in automotive or structural components, their tensile strength ensures components won’t fail under tension.

Yield Strength: 120 to 350 MPa

The yield strength of standard brass alloys ranges from 120 to 350 MPa, depending on temper and composition of the alloy. This is a measure of the stress at which the material begins to deform plastically, an essential consideration for machining operations like forming or bending. In case of components such as radiator tubes, fasteners, or marine fittings, where retention of shape under load is of utmost importance, this yield strength ensures that parts endure deformation so that machinists are assured of achieving demanding tolerances and structural integrity.

Put Your Custom Parts into Production Today!

Modulus of Elasticity: 110 GPa

The modulus of elasticity of standard brass alloys is from 110 GPa, their elastic stiffness. It measures the degree to which material resists deformation under machining force, and therefore it is ideally suited for the machining of intricate parts like connectors or valve stems. For dimensional stability applications, such as precision machining of electric or plumbing components, the modulus ensures minimal spring-back, offering reliability in holding close tolerances with machining.

Poisson’s Ratio: 0.31

Typical brass alloys have a Poisson’s ratio of approximately 0.31, illustrating the transverse strain to axial strain of the material. This offset ratio makes predictable deformation under machining, and thus the alloys can be utilized to shape complex forms like decorative hardware or precision fittings. Where precision in dimensions is a matter of concern, like in complex stampings or high-speed machining, this ratio of Poisson ensures the material deforms in an even manner, avoiding all types of unexpected distortions.

Elongation: 10% to 55%

The elongation of standard brass alloys ranges between 10% to 55%, depending on temper and content, which determines ductility. The capability of the material to stretch far without breaking comes in handy for cold forming or machining intricate components like tubing or fittings. Where extreme levels of forming are required, such as radiator cores or plumbing parts, high elongation offers parts that will not crack when formed, allowing machinists flexibility and reliability in manufacturing.

Hardness: 55 to 93 HRB

The standard hardness of common brass alloys ranges from 55 to 93 HB (Rockwell B), reflecting their cutting tool resistance. The range supports easy machinability without sacrificing durability in decorative hardware, structural components, or precision gears. In applications where surface finish and tool life are critical, such as high-speed machining, this hardness allows for tools to produce clean cuts through controlled wear, with a guarantee of consistency and effective machine results.

The following table shows the primary properties of Common brass alloys in CNC machining.

| Grades | C26000 | C27400 | C28000 | C36000 |

| Tensile Strength | 345 MPa | 385 MPa | 420 MPa | 320 MPa |

| Yield Strength | 205 MPa | 160 MPa | 240 MPa | 120 MPa |

| Elongation | 25% | 50% | 33% | 15% |

| Modulus of Elasticity | 110 GPa | 110 GPa | 100 GPa | 100 GPa |

| Poisson’s Ratio | 0.31 | 0.31 | 0.31 | 0.31 |

| Thermal Conductivity | 120 W/(m·K) | 120 W/(m·K) | 120 W/(m·K) | 120 W/(m·K) |

| Electrical Conductivity | 28% IACS | 28 % IACS | 28 % IACS | 28 % IACS |

| Hardness | 70 HRB | 80 HRB | 74 HRB | 65 HRB |

| Density | 8.58 gm/cm³ | 8.44 g/cm3 | 8.0 g/cm3 | 8.2 g/cm3 |

Does Brass Corrode?

Yes, even though Brass has excellent corrosion resistance, it corrodes in some environments. Brass corrodes very slowly in air and hardly at all in clean fresh water with a typical rate of 0.0025 to 0.025 mm per year. In seawater, it is slightly higher, 0.0075 to 0.1 mm per year. Fluorides in water have a negligible effect on brass but chlorides will lead to serious corrosion and iodides will lead to heavy damage. Brass is highly susceptible to corrosion in water containing gases like oxygen (O₂), carbon dioxide (CO₂), hydrogen sulfide (H₂S), sulfur dioxide (SO₂), and ammonia (NH₃). Brass is also susceptible to simple corrosion in mineral water, especially when iron sulfate (Fe₂(SO₄)₃) is present in it. Brass is seriously corroded by nitric acid and hydrochloric acid, but corrodes slowly in sulfuric acid. Brass surprisingly resists corrosion heavily in sodium hydroxide (NaOH) solutions.

Brass Applications

The unique properties of brass make its use possible in a range of industries.

Construction Industry: Brass is being used extensively in the construction industry for radiators, faucets, pipe fittings, fasteners, and hardware components. The greater corrosion resistance and mechanical properties make it an unavoidable material for water pipes and plumbing systems, offering longevity and reliability in wet conditions.

Electronics Industry: The high electrical conductivity of brass renders it an excellent material for electronic devices, terminals, connectors, and other electrical devices. Its high mechanical strength also renders it a good choice for electronic connectors, providing functionality along with longevity.

Musical Instruments: Brass is widely applied to the production of musical instruments such as trumpets and tubas due to its pleasing finish and characteristic acoustic characteristics. As a watchmaking material, its machinability and appearance make it a popular element in good-looking and intricate parts that enhance form and function.

Automotive and Mechanical Sector: Brass is used to make precision mechanical components like bearings, gears, and springs, and certain automotive parts. Its machinability allows for high-precision part manufacturing to withstand mechanical stress in severe applications.

Aerospace and Defense: Brass is used to manufacture precision parts for aerospace machinery and some defense industry uses. Its corrosion resistance and strength characteristics ensure guaranteed performance in applications where durability and precision are most important.

Energy Industry: Brass finds extensive use in power generation, particularly in thermal power station condensers and solar heaters and petrochemical plant equipment such as vessels, pipelines, and heat exchangers. Its excellent thermal conductivity and resistance to harsh environments make brass a reliable choice for energy applications.

About SogaWorks

SogaWorks is an all-in-one online platform for custom mechanical parts, connecting over 1,000 top-tier factories to serve startups and major companies. We offer flexible manufacturing solutions for rapid prototyping, small-volume testing, and large-scale production with services like CNC machining, 3D printing, sheet metal fabrication, urethane casting, and injection molding. With our AI-powered quoting engine, SogaWorks can deliver quotes in 5 seconds, match the best capacity, and track every step. This cuts delivery times and boosts product quality.