Acrylonitrile Butadiene Styrene (ABS) resin has balanced properties such as high strength, toughness, and versatility. This article will discuss its fundamental properties, classifications, performance characteristics, and processing techniques.

What is ABS Plastic?

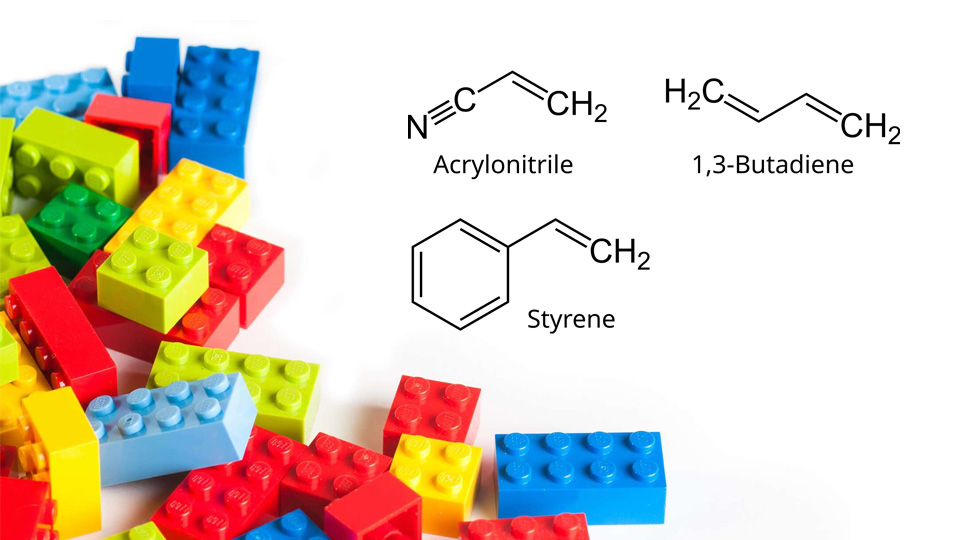

ABS resin is a ternary copolymer composed of acrylonitrile (A), butadiene (B), and styrene (S), along with its modified variants. Plastics made from ABS resin are commonly referred to as ABS plastics. This material combines the rigidity, chemical resistance, and heat resistance of polyacrylonitrile; the processability and aesthetics of polystyrene; and the impact resistance and low-temperature performance of polybutadiene.

ABS resin typically appears as pale-yellow granules or powder. It is non-toxic, odorless, lightweight (with a density of 1.04–1.07 g/cm³), and offers excellent impact resistance, good low-temperature performance, and chemical resistance. It also boasts dimensional stability, high surface gloss, and ease of coating and coloring. However, ABS has some limitations: it is flammable, has a relatively low heat deflection temperature, and exhibits poor weather resistance.

Types and Performance of ABS

ABS resin can be tailored over a wide range of compositions and structures to meet specific performance needs.

| Types | Advantage | Disadvantage | Application |

| General Purpose ABS | Good mechanical properties, cost-effective | Poor heat and weather resistance | Household appliances, toys, office equipment, etc. |

| High Impact ABS | Very high impact resistance, better toughness | Higher cost, increased processing difficulty | Automotive parts, safety helmets, sports equipment, etc. |

| High Flow ABS | High fluidity, easily fills complex molds | Possible reduction in mechanical strength | Precision parts, thin-walled products, electronic device structures, etc. |

| Flame Retardant ABS | Improved flame resistance, enhanced safety | Increased cost, may affect some mechanical properties | Increased cost may affect some mechanical properties |

| Plating Grade ABS | High surface finish, suitable for plating | Higher cost, specific processing requirements | Decorative metal pieces, automotive interior and exterior trim, decorative panels for electronics, etc. |

Mechanical Properties

The tensile strength of ABS varies significantly by grade, typically ranging from 33 to 52 MPa. ABS is renowned for its exceptional impact strength. High-impact ABS grades can achieve a notched Izod impact strength of approximately 400 J/m at room temperature, retaining values above 120 J/m even at -40°C. This is due to ABS’s two-phase structure: a continuous resin phase with dispersed rubber particles. These rubber particles absorb impact energy, preventing crack propagation and enhancing toughness.

Impact performance depends on factors like rubber content, grafting degree, and particle size. Higher rubber content (typically 25 – 40% by mass) significantly boosts impact strength, but excessive rubber can reduce other mechanical properties, such as tensile strength and elastic modulus.

ABS also exhibits excellent creep resistance. For instance, ABS pipe samples subjected to 7.2 MPa at room temperature show negligible dimensional changes even after two and a half years. While not suitable as a self-lubricating material, ABS’s good dimensional stability makes it viable for medium-load bearings due to its decent wear resistance.

Electrical Properties

ABS resin offers reliable electrical insulation across a broad frequency range, with minimal influence from temperature or humidity. Its electrical properties are summarized in the Table.

| Property | 60Hz | 10³Hz | 10⁹Hz |

| Dielectric Loss (23°C) | 3.73 – 4.01 | 2.75 – 2.96 | 2.44 – 2.85 |

| Dielectric Loss Factor (23°C) | 0.004 – 0.007 | 0.006 – 0.008 | 0.008 – 0.010 |

| Volume Resistivity (Ω·cm) | (1.05 – 3.60) × 10¹⁶ | (1.05 – 3.60) × 10¹⁶ | (1.05 – 3.60) × 10¹⁶ |

| Surface Resistivity (s) | 66 – 82 | 66 – 82 | 66 – 82 |

| Breakdown Voltage (kV/mm) | 14 – 15 | 14 – 15 | 14-15 |

Thermal Properties

The heat deflection temperature (HDT) of ABS under a 1.82 MPa load is approximately 93°C but can increase by 6–10°C with annealing. Due to its amorphous structure, ABS exhibits a stable stress-temperature response, with HDT increasing only 4–8°C when the load drops to 0.45 MPa. Heat-resistant ABS grades can achieve an HDT of around 115°C. The brittle temperature of ABS is -7°C, but it retains considerable strength at -40°C. ABS products are typically used within a temperature range of -40°C to 100°C.

The linear coefficient of thermal expansion for ABS ranges from 6.4×10⁻⁵/°C to 11.0×10⁻⁵/°C, which is relatively low among thermoplastics. However, ABS has lower thermal stability compared to other engineering plastics, decomposing at 260°C and releasing toxic volatile compounds. It is also flammable and lacks self-extinguishing properties.

Chemical Properties

ABS resin demonstrates good chemical resistance, largely due to its nitrile groups, which make it resistant to dilute acids, alkalis, and salts. However, it dissolves in ketones, aldehydes, esters, and chlorinated hydrocarbons. While insoluble in most alcohols like ethanol, ABS softens in methanol after several hours. Prolonged contact with hydrocarbon solvents can cause swelling. Under stress, ABS is susceptible to stress cracking from chemicals like acetic acid and vegetable oils. Table 1-4 (placeholder: insert chemical resistance table here) details changes in mass and appearance after prolonged exposure to various chemicals.

Types of Modified ABS Resins

Despite its many advantages, ABS has limitations as an engineering plastic, including insufficient strength, low heat deflection temperature, poor weather resistance, lack of self-extinguishing properties, and opacity. To address these, several modified ABS variants have been developed, including reinforced ABS, flame-retardant ABS, transparent ABS, ASA, ACS, and MBS resins.

Reinforced ABS

Adding 20 – 40% (by mass) glass fiber significantly enhances ABS’s tensile strength, flexural strength, and modulus, while also increasing HDT and reducing the coefficient of thermal expansion for improved dimensional stability. However, impact strength decreases with higher glass fiber content. Table 2-1 (placeholder: insert reinforced ABS properties table here) summarizes the performance of glass fiber-reinforced ABS.

Flame-Retardant ABS

ABS is inherently flammable, but flame-retardant ABS can be produced by incorporating low-molecular-weight organic flame retardants and synergists. This variant is ideal for electronic and electrical applications requiring flame resistance and good mechanical strength, such as TV housings and radomes.

Transparent ABS

Standard ABS is opaque, but transparent ABS can be achieved by incorporating methyl methacrylate into the acrylonitrile, butadiene, and styrene components through graft copolymerization. Transparent ABS offers high transparency, excellent solvent resistance, and strong impact strength.

ASA Resin

ASA (acrylonitrile-styrene-acrylate) resin is a ternary copolymer made by grafting acrylonitrile and styrene onto acrylic rubber. Also known as AAS resin, ASA excels in weather resistance, impact resistance, thermal stability, and chemical resistance. It is widely used in automotive components like body panels, fuel tanks, radiator grilles, and tail light covers. The table lists the performance of ASA resin.

| Density (g/cm³) | 1.07 |

| Tensile Strength (MPa) | 52 |

| Elastic Modulus (GPa) | 2.6 |

| Elongation(%) | 15 |

| Bending Strength (MPa) | 85 |

| Heat Deflection Temperature/℃ | 88 |

| Hardness(R) | 85 |

ACS Resin

ACS (acrylonitrile-chlorinated polyethylene-styrene) resin is a ternary copolymer formed by grafting acrylonitrile and styrene onto hydrogenated polyethylene. It offers excellent weather resistance and flame retardancy. The table lists the details of the performance of ACS resin.

| Density (g/cm³) | 1.07 |

| Tensile Strength (MPa) | 32 |

| Elongation(%) | 40 |

| Heat Deflection Temperature /℃ | 86 |

| Molding Shrinkage Rate (%) | 0.4 |

MBS Resin

MBS (methyl methacrylate-butadiene-styrene) resin is a graft copolymer of methyl methacrylate, butadiene, and styrene. Replacing acrylonitrile with methyl methacrylate yields a transparent material with up to 90% light transmittance. MBS retains good impact strength and toughness at -40°C, along with resistance to inorganic acids, alkalis, salts, and oils, though it is less resistant to ketones, aromatic hydrocarbons, aliphatic hydrocarbons, and chlorinated hydrocarbons. The table summarizes the performance of MBS resin from Shanghai Pen Chemical Factory.

| Density (g/cm³) | 1.10-1.14 |

| Tensile Strength (MPa) | 40 |

| Bending Strength (MPa) | 40 |

| Heat Deflection Temperature/℃ | 75-80 |

| Molding Shrinkage Rate (%) | 0.4-0.6 |

Processing Properties and Technology of ABS Plastics

Flow Properties

ABS resin has a melt flow rate (MFR) typically ranging from 0.02 to 1 g/min (200°C, 5 kg), with some grades outside this range. Higher MFR indicates better flowability. ABS with an MFR below 0.1 g/min is suitable for extrusion, while an MFR above 0.1 g/min is ideal for injection molding. As a pseudoplastic fluid, ABS exhibits shear-thinning behavior, allowing viscosity adjustments via shear rate. For consistent product quality, operate at shear rates where viscosity is less sensitive to fluctuations. ABS has moderate melt viscosity—less fluid than polyamide but more so than polycarbonate—with a relatively fast cooling and solidification rate.

Thermal Properties

As an amorphous polymer, ABS lacks a distinct melting point, with a glass transition temperature (Tg) of about 115°C. Processing temperatures must exceed this, typically staying below 250°C to avoid decomposition, which occurs above 260°C, releasing toxic volatiles. Recommended processing temperatures are:

- Injection molding: 160–230°C

- Extrusion: 160–195°C

- Blow molding: 200–240°C

- Vacuum forming: 140–180°C

The temperature range between the flow temperature and decomposition temperature determines processing ease. ABS’s relatively low melt temperature (160–190°C) and broad processing window make it easy to process. However, high processing temperatures require shorter residence times to prevent chemical reactions. Adding heat stabilizers can widen the processing window and extend allowable residence times. Due to its poor thermal stability, minimize residence time and clean the machine barrel after processing.

Drying Characteristics

ABS’s polar cyano groups result in higher water absorption (0.3%–0.8%, less than 1%) compared to polystyrene but less than polyamide. Pre-drying is essential before processing to reduce the moisture content below 0.1%. Dry at approximately 80°C for 2–4 hours, using methods like circulating air drying (70–80°C, 4+ hours) or conventional oven drying (80–100°C, 2 hours, granule layer thickness <50 mm).

Injection Molding

ABS is typically processed using screw-type injection molding machines with a single-head, equidistant, gradual, full-thread screw (length-to-diameter ratio of 20, compression ratio of 2.0–2.5). Open or extended nozzles are preferred over self-locking nozzles to avoid flow reduction or material discoloration.

Injection temperatures vary by grade:

- General-purpose and high-impact grades: 200–260°C (lower to prevent decomposition)

- Heat-resistant and plating grades: 220–270°C (higher for better mold filling or plating performance)

- Flame-retardant grades: 190–240°C

Higher injection pressures are needed for thin-walled parts, long flow paths, small gates, or heat-resistant/flame-retardant grades, while lower pressures suffice for thick-walled parts with large gates. To minimize internal stress, holding pressure should not be excessive. Mold temperatures are typically 50°C but can be raised to 70°C to improve surface finish, reduce weld lines, and minimize deformation. The table lists processing conditions for various ABS grades.

| Parameter | General Type | High-Thrust Type | New Type | Single-Stage |

| Rotation Speed (r/min) | 30–60 | 30–60 | 30–60 | 20–60 |

| Nozzle Temp (°C) | 180–190 | 190–200 | 190–200 | 190–210 |

| Nozzle Temp (°C) After | 180–200() | 180–200 | 190–200 | 200–210 |

| Engine Temp (°C) Middle | 210–230 | 210–230 | 220–240 | 230–250 |

| Engine Temp (°C) Front | 200–210 | 200–210 | 200–220 | 210–230 |

| Ignition Temp (°C) | 50–70 | 50–80 | 60–85 | 40–80 |

| Main Pressure (MPa) | 70–90 | 70–120 | 85–120 | 70–120 |

| Operating Pressure (MPa) | 50–70 | 50–70 | 50–80 | 50–70 |

| Injection Time (s) | 3–5 | 3–5 | 3–5 | 1–4 |

| Holding Time (s) | 15–30 | 15–30 | 15–30 | 20–50 |

| Cooling Time (s) | 15–30 | 15–30 | 15–30 | 15–30 |

| Total Cycle (s) | 40–70 | 40–70 | 40–70 | 40–90 |

Extrusion

ABS extrusion uses general-purpose single-screw extruders (length-to-diameter ratio of 18–20, compression ratio of 2.5–3.0), with gradual or abrupt compression screws. The moderate melt viscosity eliminates the need for screw cooling. Extrusion produces ABS profiles like pipes, rods, and sheets. The table lists detailed processing conditions for ABS pipes and rods, respectively.

| Parameter | General Value |

| Shaft Outer Diameter (mm) | 32.5 |

| Shaft Inner Diameter (mm) | 25.5 |

| Temperature (°C) Range Lower | 160–165 |

| Temperature (°C) Range Upper | 170–175 |

| Temperature (°C) Peak | 175–180 |

| Ignition Temperature (°C) | 175–180 |

| Operating Temperature (°C) | 190–195 |

| Rotation Speed (r/min) | 10.5 |

| Inner Diameter (mm) | 33 |

| Outer Diameter (mm) | 26 |

| Flat Straight Outer Length (mm) | 50 |

| Position Ratio | 1.02 |

| Outer Fixed Weight Inner Diameter (mm) | 33 |

| Outer Fixed Length (mm) | 250 |

About SogaWorks

SogaWorks is an all-in-one online platform for custom mechanical parts, connecting over 1,000 top-tier factories to serve startups and major companies. We offer flexible manufacturing solutions for rapid prototyping, small-volume testing, and large-scale production with services like ABS CNC machining, 3D printing, urethane casting, and injection molding. With our AI-powered quoting engine, SogaWorks can deliver quotes in 5 seconds, match the best capacity, and track every step. This cuts delivery times and boosts product quality.