CNC Nylon Machining Service

Our Nylon machining service delivers precision prototypes with strength, wear resistance and low friction. Get instant quotes on nylon PA6/PA66 parts.

All drawings are secure and confidential.

What is Nylon?

Nylon, or Polyamide (PA), is an engineering plastic with unique mechanical properties, superior corrosion resistance, oil resistance, heat resistance, and high modulus. By reinforcing and flame-retardant modification, its heat resistance, dimensional stability, and flame retardancy can be significantly improved. The most common colors of nylon are black, white, and natural shades (grayish-white or beige). it is widely used in the automotive, electronics, electrical industries.

Based on how plastic reacts to heat, nylon is classified as a thermoplastic material. it becomes liquid at their melting point (220 degrees Celsius for PA). A key property of thermoplastics is that they can be heated to their melting point, cooled, and reheated without significant degradation.

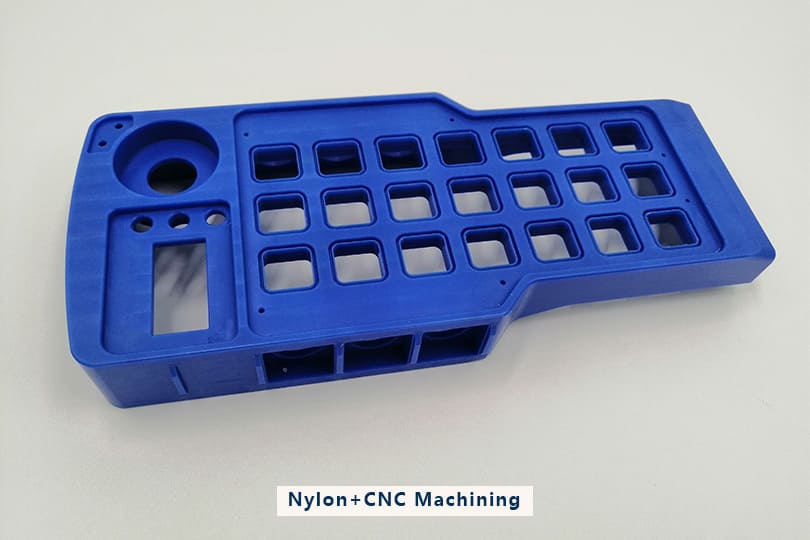

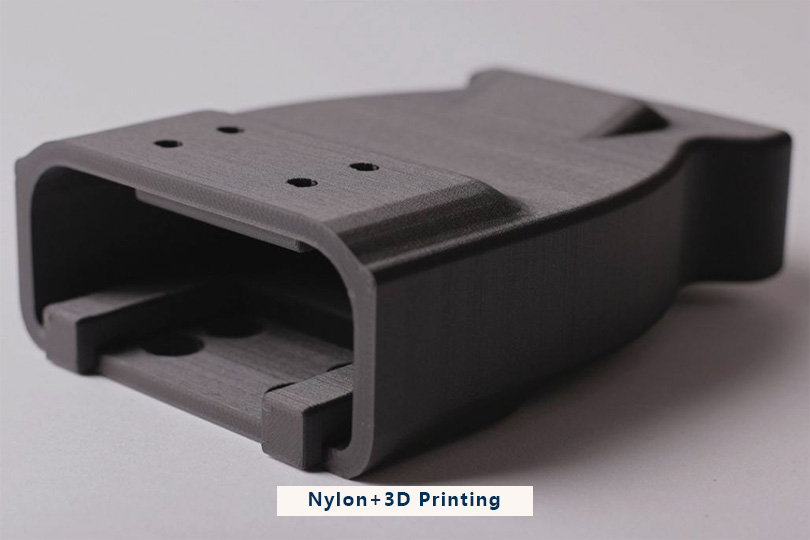

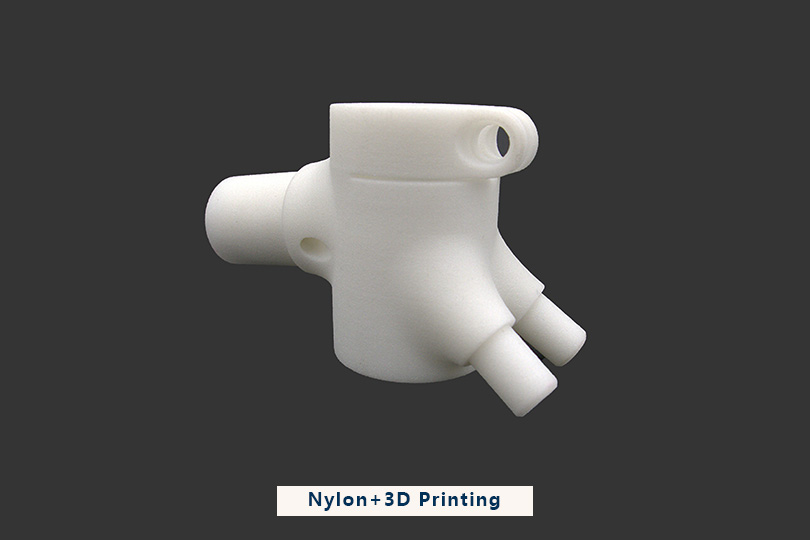

Gallery of Nylon Machined Parts

Here are some of nylon parts we produced for our valued customers all over the world.

Advantages of Nylon in Machining

Advantages

- High Strength: Its tensile strength exceeds that of metals, while its yield strength is comparable to that of metals, although its rigidity is lower than that of metals. Its tensile strength is close to its yield strength, more than twice that of ABS. It has strong absorption capabilities for impact and stress vibrations, with impact strength much higher than that of general plastics.

- Excellent Fatigue Resistance: Good fatigue resistance ensures that components maintain their original mechanical strength even after multiple repeated flexures.

- Smooth Surface: The surface is smooth with a low coefficient of friction. It has self-lubricating properties when used as a moving mechanical component, resulting in low noise. Lubricants may not be necessary under moderate friction conditions; however, if lubrication is needed to reduce friction or aid in heat dissipation, options include water, oil, and grease. Consequently, its service life as a transmission part is long.

- Corrosion Resistance: It is highly resistant to alkali and most salt solutions, as well as weak acids, lubricating oil, gasoline, aromatic compounds, and general solvents. It can withstand erosion by gasoline, oil, fat, alcohol, weak alkali, and has excellent aging resistance.

Notes

- Excellent electrical properties: Good electrical insulation, with nylon having a high volume resistivity and high breakdown voltage. It can be used as insulation material for power frequency in dry conditions, and still maintains good electrical insulation even in high humidity environments.

- Poor light resistance: In long-term high-temperature environments, it will undergo oxidation with oxygen in the air, initially turning brown and then cracking.

- Machining Requiring Strict Standards: Due to thermal expansion, it is difficult to control the dimensional stability of the product; the presence of sharp corners can cause stress concentration, reducing mechanical strength; uneven wall thickness can lead to warping and deformation of the part.

Grades of Nylon and Properties

Nylon is a commonly used engineering plastic. There are many varieties, but the main varieties are PA6 and PA66, which are dominant, followed by PA11, PA12, etc. In nylon molding, nylon is sometimes filled with a certain percentage of glass fiber, that is, Glass Filled, to increase its tensile strength. The percentage of glass fiber is usually between 10% and 40%. In the material library of SogaWorks, there are mainly three materials: PA6, PA66, and PA Glass Filled. If you have processing needs for other varieties, we can also customize them for you. Please consult our account manager for details.

Properties |

PA 6 |

PA 66 |

PA66 Glass Filled |

|---|---|---|---|

|

Tensile Strength |

79 MPa |

85 MPa |

180 MPa |

|

Flexural Strength |

100 MPa |

110 MPa |

260 MPa |

|

Elongation |

60% |

70% |

10% |

|

Elastic Modulus |

4 GPa |

3 GPa |

20 GPa |

|

Impact Strength |

30 kJ/㎡ |

16 kJ/p'f'm |

80 kJ/p'f'm |

|

Melting Temp. |

220 °C |

258 °C |

260 °C |

|

Service Temp. (short time) |

160 °C |

170 °C |

200 °C |

|

Density |

1.14 g/cm³ |

1.15 g/cm³ |

1.29 g/cm³ |

Nylon Machining Processes

Nylon is suitable for a variety of manufacturing processes such as precision subtractive processes, flexible 3D printing, and efficient injection molding. The selection of nylon machining technology needs to consider multiple factors such as material properties (hygroscopicity), design complexity (complex inner cavity/thin wall) and costs.

- CNC Machining: Achieving ±0.01mm tolerance cutting with five-axis CNC machines is ideal for small-batch prototyping and complex component production.

- 3D Printing: SLS or FDM printing technology enables moldless manufacturing and rapid verification of the structure and functionality.

- Injection Molding: The process has the highest mass production efficiency but the mold fee is relatively expensive. It is suitable for large-volume parts production.

- Cutting parameters should be set reasonably based on the type of nylon material, tool characteristics, and machine tool properties. Generally, smaller cutting depths and moderate feed speeds help improve machining quality and extend tool life.

- Nylon is relatively soft and tough. Carbide tools are suitable for machining nylon because they offer higher wear and heat resistance.

- Before machining, ensure the nylon is dry. You can properly heat the nylon in a drying oven to reduce its moisture content, preventing moisture-related impacts on accuracy and quality.

- For finish machining, it’s recommended to use a smaller cutting depth and higher feed rate to achieve a smoother surface.