CNC Bronze Machining

Bronze is essential in CNC machining due to its low friction, great machinability and high wear resistance. Get quick-turn prototypes and production bronze parts in days.

All drawings are secure and confidential.

Bronze Alloys for CNC Machining

Copper 932 (SAE 660)

A high-copper alloy with tin and zinc, valued for strength and self-lubricating properties. Used in bearings and aerospace parts.

Silicon Bronze

Combines copper, silicon, and zinc for strength and a sleek finish, common in valve and pump components.

Aluminum Bronze

With 6–12% aluminum, it excels in strength and seawater resistance, used in naval and oil industry equipment.

Phosphor Bronze

Tin and phosphorus enhance durability and low friction, suitable for springs and electrical parts.

Copper-Nickel

With 2–30% nickel, it provides thermal stability for marine and electronic applications.

Manganese Bronze

Up to 3% manganese ensures shock resistance, used in propellers and pump parts.

* Generalized values. For reference only.

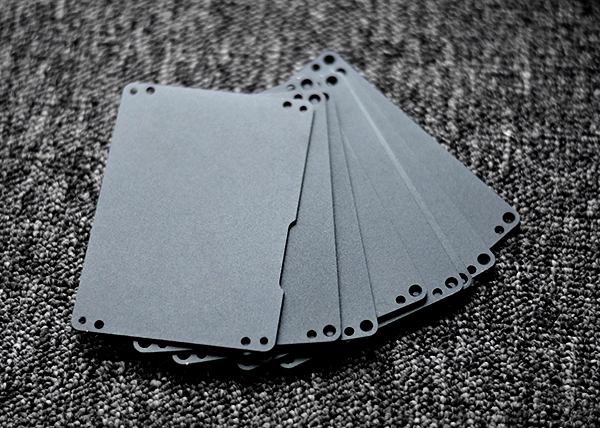

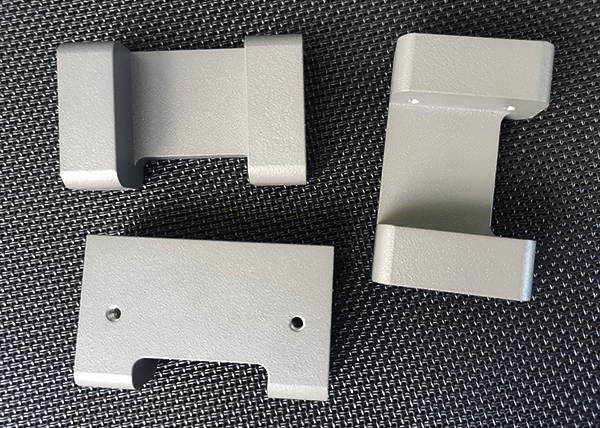

Surface Finishes for Bronze Machined Parts

Bronze can be polished in several ways to improve its performance and looks. As-machined, bead blasting and chemical coatings are the three most common surface treatments for bronze.

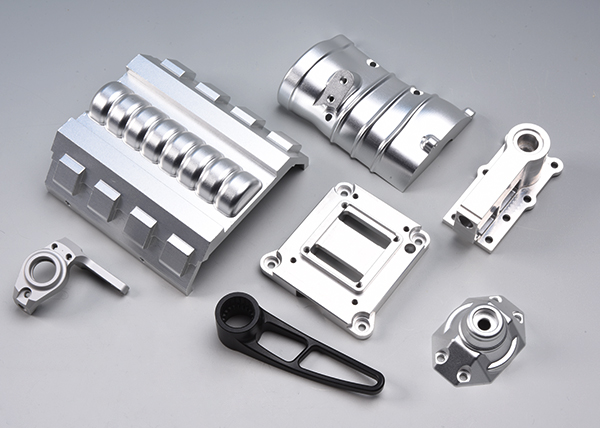

Gallery of CNC Machined Bronze Parts

Advantages

- Superior Workability: Its soft composition enables precise cuts with minimal tool wear, ideal for detailed designs

- Corrosion Immunity: Bronze resists degradation in harsh conditions, such as seawater, making it perfect for marine and chemical settings

- Strength-Malleability Balance: It provides durability while remaining pliable for diverse applications

- Low Friction: A reduced friction coefficient minimizes wear in components like bushings and bearings

Notes

- Tool Degradation: Its softness can accelerate tool wear, increasing maintenance costs

- Detail Limitations: Complex features may be harder to achieve due to bronze’s pliability

- Slower Processing: Softer materials often require cautious machining speeds, lengthening production times

CNC Bronze Machining Process

The process starts with a digital blueprint created via CAD (Computer-Aided Design) software, which is translated into machine instructions using CAM (Computer-Aided Manufacturing) tools. The bronze workpiece is clamped onto the CNC machine’s platform, and the system is loaded with the design file and toolpath data. Machining techniques include:

- CNC Milling: Shaping flat or curved surfaces.

- CNC Turning: Forming cylindrical bronze components.

- 5-axis Machining: Creating intricate, multi-angle parts.

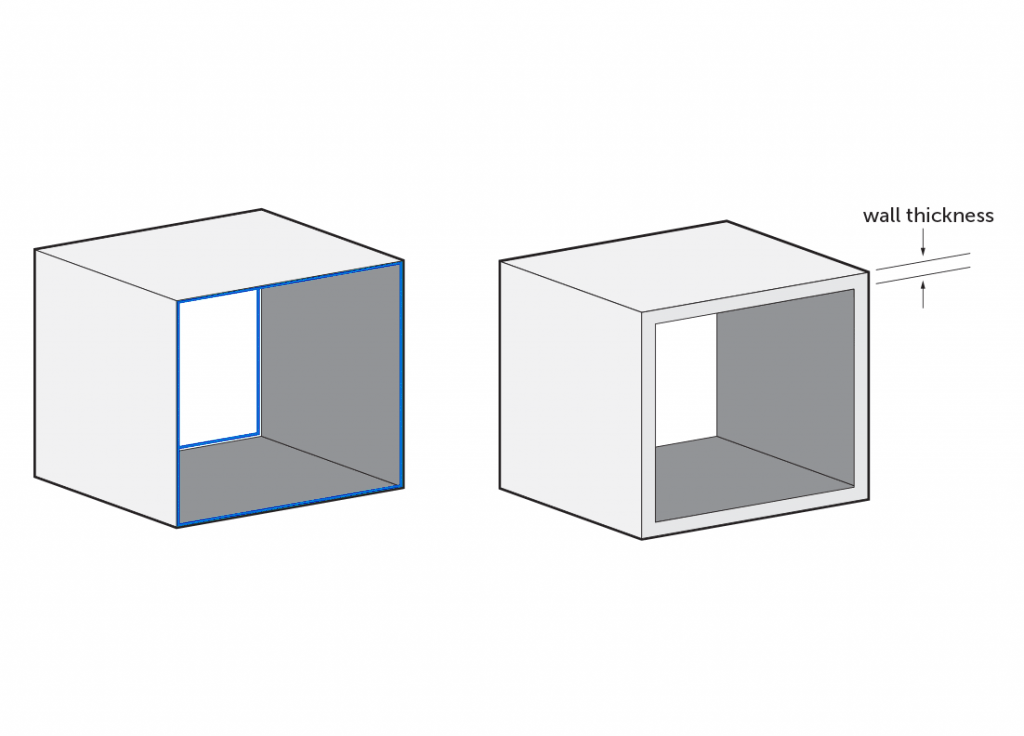

Cost-Effective Design Strategies

- Choose the Right Alloy. Match bronze type to project demands for optimal performance and cost.

- Balance Wall Thickness. Avoid overly thin walls that risk deformation or thick ones that waste material.

- Simplify Geometries. Reduce undercuts to lower machining complexity

- Round Edges. Use fillets to minimize stress concentrations, improving durability