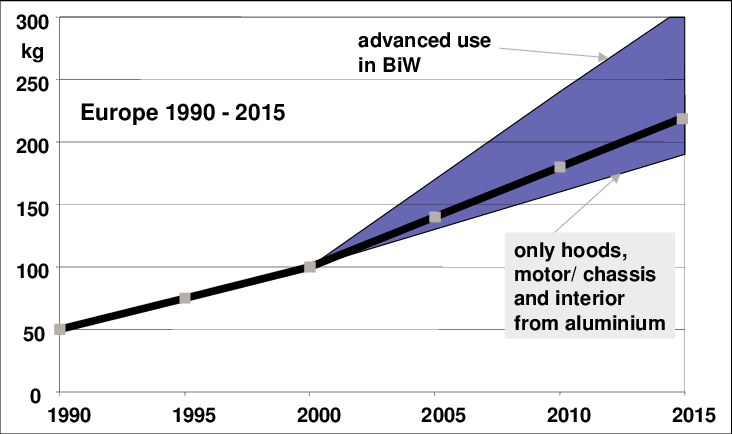

European vehicles used an average of 102 kg of aluminum in components in 2000, including 59 kg for engine parts, 11 kg for structural components, 6 kg for chassis, 5 kg for body-in-white, and 21 kg for other parts. With technological advancements and growing market demand, aluminum usage in small to mid-sized vehicles has increased, now it ranges from 50 to 200 kg per vehicle, as shown in Figure 1. In some cases, such as the Audi A2 and high-end A8 models, aluminum usage reaches up to 300 kg and 550 kg, respectively.

Figure 1: Average use of aluminum per car in Western Europe

Aluminum Alloys in Powertrains

Most aluminum supplied to the automotive market is used in powertrain systems. On average, European-produced vehicles contain about 80 kg of aluminum in their powertrains, accounting for 55-60% of the total aluminum content. In North America and Southeast Asia, this proportion is even higher, reaching 65-70%.

The majority of aluminum powertrain components (80-85%) are castings, produced using various casting techniques. These casting alloys typically contain silicon, magnesium, and copper, with alloying elements making up to 20% of the composition. Many cast aluminum alloys are made from recycled aluminum, often sourced from post-consumer scrap, such as recycled vehicles. Components made from wrought aluminum alloys are less common, with roughly 10% from rolled sheets, 5% from extruded aluminum, and about 1% from forged aluminum.

Aluminum is the preferred material for powertrain applications, having effectively dominated the passenger car powertrain market with near-complete market penetration. For instance, over 50 years ago, aluminum replaced copper or brass as the primary material for heat exchangers and is now the only material used in these applications. Aluminum is also virtually the only material used for pistons. For cylinder heads, transmission housings, and many auxiliary components, full market penetration is rapidly approaching. Recently, engine blocks have been the largest driver of aluminum growth, initially in gasoline engines and now in diesel engines, displacing cast iron. However, further growth potential in powertrains is limited. In some applications, other lightweight solutions, such as high-performance plastics for parts not exposed to high temperatures and cast magnesium solutions, are beginning to replace aluminum castings. As global trends push for smaller, more fuel-efficient vehicles, the absolute amount of aluminum used in powertrain components (engines, transmissions, and drivetrain parts) may decline.

Applications of aluminum in powertrain components include:

- Pistons

- Engine blocks

- Cylinder liners

- Cylinder heads

- Fuel systems

- Heat shields

- Heat exchangers

- Other engine components

- Transmission systems

Suppliers of engine blocks are continuously working to produce better, lighter blocks to improve engine efficiency. The engine block (or cylinder block/crankcase) is the largest and most complex single metal component in an internal combustion engine, accounting for 3-4% of a vehicle’s total weight. As such, it plays a critical role in weight reduction efforts. Aluminum casting alloys can reduce engine block weight by 40-55%. Additionally, both engine blocks and cylinder heads require materials with excellent thermal conductivity and corrosion resistance, areas where aluminum alloys excel.

The use of aluminum engine blocks began in the late 1970s for gasoline engines. Due to more demanding technical requirements, cast iron replacement in diesel engines was limited until the mid-1990s. As diesel engine production increased, the need for lightweight design standards grew, and by around 2005, aluminum engine blocks achieved a 50% market share, with penetration continuing to rise. Today, gasoline engine blocks are typically made of aluminum, and with ongoing alloy advancements, their use in diesel engine blocks is also growing rapidly.

Figure 2: Ford Mustang Shelby GT500 engine block, produced by Honsel using patented low-pressure sand casting and innovative cylinder bore coating technology

Commonly used alloys for engine blocks include EN AC-46200 (AlSi8Cu3) and EN AC-45000 (AlSi6Cu4), which are similar to U.S. standard alloys A380.2 and A319, respectively. These hypoeutectic aluminum-silicon alloys, often made from recycled aluminum, are primarily used in gravity casting processes for engine blocks. Their relatively high copper content allows them to maintain strength at elevated temperatures and makes them easy to machine. Components are typically used in as-cast (F) condition or with T4 or T5 heat treatments. While T6 tempering is possible, T5 stabilization tempering is often sufficient for many designs. Nearly all high-pressure die-cast engine blocks are made from the common secondary alloy EN AC-46000 (AlSi9Cu3(Fe)).

Pistons are made from cast or forged high-temperature-resistant aluminum-silicon alloys. There are three main types of aluminum alloys. The standard alloy is a eutectic Al-12%Si alloy with about 1% each of copper, nickel, and magnesium. For improved high-temperature strength, specialized eutectic alloys with 18% and 24% silicon (hypereutectic) have been developed, offering lower thermal expansion and wear but reduced strength. In practice, piston suppliers use a wider range of optimized alloy compositions, generally based on these types. Most pistons are produced using gravity die casting. Optimized alloy compositions and controlled solidification conditions enable the production of lightweight, high-strength pistons. Forged pistons made from eutectic or hypereutectic alloys exhibit higher strength and are used in high-performance engines where pistons endure greater stress. Forged pistons with the same alloy composition have a finer microstructure than cast pistons, and the forging process provides greater strength at lower temperatures, allowing for thinner walls and reduced piston weight.

Figure 3: Aluminum Alloy Piston

Aluminum Alloy Wheels

Aluminum alloy wheels have increasingly replaced steel wheels due to their lightweight, excellent heat dissipation, and attractive appearance. Over the past decade, aluminum alloy wheels have grown at an annual rate of 7.6%, with analyses indicating that by 2010, the aluminum penetration rate for wheels reached 72-78%. A365 is a casting aluminum alloy with good casting properties and high overall mechanical performance, widely used for cast aluminum wheels worldwide.

Figure 4: Aluminum Alloy Wheel

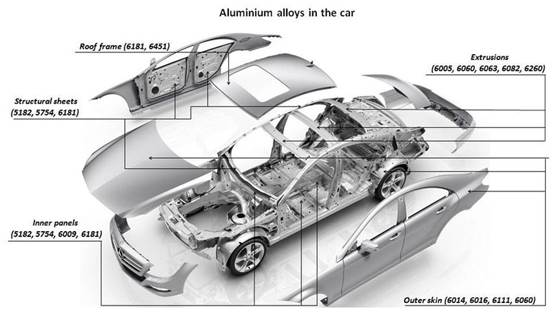

Aluminum Alloy Body Solutions

In the early days of automotive and aluminum production, aluminum sheets were used for vehicle bodies. However, during the era of mass production and cost prioritization, steel became dominant. Steel bodies are traditionally made from stamped sheet parts joined by resistance spot welding. The introduction of high-strength and ultra-high-strength steel grades has enabled improved rigidity and crash resistance and/or weight reduction with minimal additional cost.

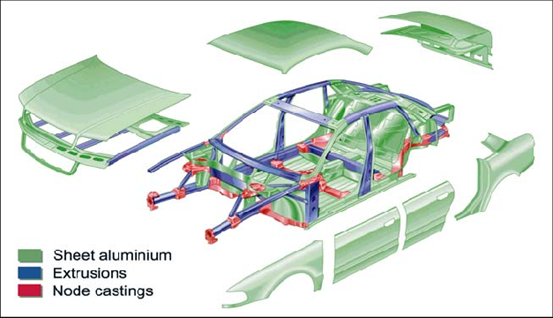

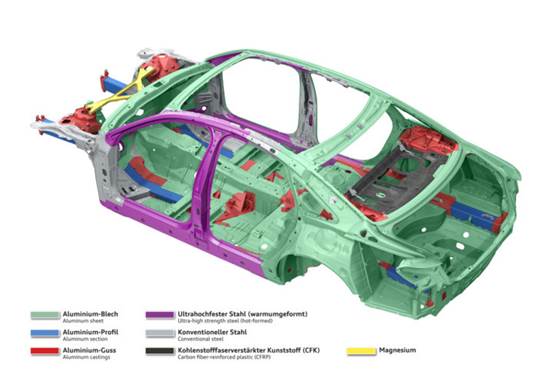

Design and manufacturing principles similar to steel body structures can be applied to achieve all-aluminum bodies. However, the significant performance differences between steel and aluminum mean that simple material substitution does not always yield cost-optimized solutions. A holistic approach is required, considering the entire system of construction materials, appropriate design concepts, and applicable manufacturing methods. Promising aluminum body concepts, such as Europe’s Aluminum Space Frame (ASF) and Tesla’s integrated casting approach, result from aluminum-oriented design and corresponding manufacturing technologies.

Compared to steel, one of aluminum’s key advantages is the ability to produce extrusions with complex cross-sections, single- or multi-cavity profiles, and thin-walled, complex-shaped castings with excellent mechanical properties. These components can serve not only load-bearing or reinforcing functions but also as connecting elements. The proper use of extruded or die-cast products enables innovative structural design solutions, significantly reducing weight and cost through component integration and the addition of extra functionality.

When aluminum sheet thickness is increased by 40%, it exhibits dent and bending stiffness similar to steel, achieving a 50% weight reduction through material substitution. For profiles, aluminum’s potential for weight reduction is particularly significant when profile geometry can be modified, such as switching from open to closed profiles or introducing multi-cavity profiles. Additionally, when profile diameter can be increased, extruded aluminum profiles offer clear advantages.

Aluminum alloys have a much lower melting point than steel or iron, making casting easier.

Key elements of aluminum alloy monocoque body structures include:

- Load-bearing profiles

- Reinforcing panels

- Connecting elements

Figure 5: Sheet + Profile + Node Aluminum Alloy Body

Aluminum Alloy Body Examples

Sheet-intensive body design concepts, established and validated for steel bodies, can also be implemented with aluminum sheets, though not as easily as with steel. Aluminum alloys are still considered a premium material for mid- to high-end vehicles. The Panhard Z1, introduced in 1953, is an early example, using EN AW-5754 (AlMg3) alloy sheets in series production. In the early 1980s, several aluminum concept cars were developed, often simply replacing steel sheets with aluminum in existing models. For example, at the 1981 Frankfurt Motor Show, a Porsche 928 with an all-aluminum body was showcased, developed in collaboration with Alusuisse using Anticorodal®-120 (EN AW-6016) alloy sheets (1.2 mm for closures, 2.5 mm for structural parts). The aluminum body weighed 161 kg, 106 kg lighter than its steel counterpart. Shortly afterward, Audi began extensive aluminum research, developing an aluminum body based on the Audi 100.

Figure 6: Audi 100 Aluminum Sheet Concept Car (1985)

The first mass-produced all-aluminum body vehicle was Honda’s 1989 Acura NSX, a high-performance two-seater sports car built in limited quantities by hand. It featured a 163 kg all-aluminum monocoque body with some extruded aluminum profiles in the frame and suspension. The aluminum body alone reduced weight by nearly 200 kg compared to a steel body, with the aluminum suspension saving an additional 20 kg. A specialized paint process, including an aircraft-grade chromate coating for chemical protection, was used. The body structure, made from high-strength aluminum alloys and advanced construction techniques, was 40% lighter yet stronger than comparable steel bodies, joined using a combination of spot welding and MIG welding.

Following the NSX, Audi achieved the first large-scale production of an all-aluminum body with the 1993 Audi A8 ASF (Audi Space Frame), unveiled at the Frankfurt Motor Show. A year later, the production version was launched at the Geneva Motor Show. The ASF technology extensively used aluminum alloys for both the body-in-white and outer panels, a technology later applied to models like the A2, TT, and R8.

Figure 7: Audi Space Frame Body

Rising fuel prices, CO2 regulations, and increasing comfort and equipment demands have driven a strong trend toward lightweighting. Enhanced comfort and sporty driving have also spurred innovation in lightweight design and engineering, promoting the use of aluminum alloy sheets in vehicles. Today, beyond Audi, many luxury brands, such as Jaguar Land Rover, extensively use all-aluminum bodies. Ford has also introduced aluminum alloys in its iconic F-150 pickup truck.

Extruded Profiles

Advanced aluminum extrusion technology has opened up a wide range of solutions and applications. Complex profile shapes enable innovative, lightweight designs with integrated functionality. In Europe, flexible vehicle concepts like the Aluminum Space Frame (ASF) and complex substructures (e.g., chassis components, bumpers, crash elements, and airbag components) have been developed using aluminum profiles. These offer high potential for complex designs and functional integration, making them ideal for cost-effective mass production.

Put Your Custom Parts into Production Today!

Medium-strength 6xxx and high-strength 7xxx age-hardenable alloys are commonly used in extrusion processes, with formability and final strength controlled by subsequent aging treatments. Extrusions are widely used in bumper beams, crash boxes, and other components, representing a major market for aluminum profiles.

Aluminum Alloy Sheets

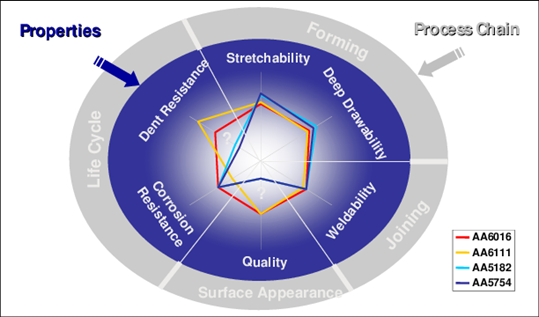

The main aluminum alloy categories for automotive sheet applications are non-heat-treatable Al-Mg (5xxx series) and heat-treatable Al-Mg-Si (6xxx series) alloys, some of which are tailored for specific properties, such as optimized Al-Mg alloys for chassis strength and corrosion resistance or Al-Mg-Si alloys for body panels with improved formability, surface appearance, and age-hardening response. Specific properties and key differences are illustrated in Figure 13. The effects of alloying elements and process parameters contribute to enhanced performance and efficient manufacturing.

Figure 8: Comparison of 5xxx and 6xxx Series Aluminum Alloys

The 6xxx series alloys, containing magnesium and silicon, include both copper-containing and copper-free variants. Currently used 6xxx alloys for body panels include 6009, 6010, 6016, 6111, and the newer 6181A for recycling. In the U.S., AA6111 is commonly used for 0.9-1.0 mm outer panels, offering high strength and good formability. In Europe, EN-6016 is preferred for gauges of about 1-1.2 mm, providing superior formability, better filiform corrosion resistance than high-copper alloys, and flat edges even on locally pre-deformed parts. However, its bake-hardening strength is notably lower than 6111. The supply balance for 5xxx and 6xxx automotive sheet alloys is increasingly shifting toward 6xxx alloys, driven by OEM demand for higher strength, which is more easily achieved with 6xxx alloys. These alloys account for at least 80% of the current automotive sheet supply. The 6xxx series offers versatility, heat-treatability, high formability, and weldability.

Non-heat-treatable 5xxx Al-Mg-Mn alloys, with excellent formability restored through intermediate annealing, are widely used for complex-shaped automotive components. Their age-hardening does not require quenching, supporting high-consistency tolerances. A successful example is chassis components, such as the BMW 5 Series rear axle subframe, made from 3.5-4.0 mm sheets using hydroforming and welded tubes for high functional integration. The new BMW 7 Series combines tubes and castings, with a total weight of just 14.1 kg.

Body Examples

- Framework: The most load-bearing parts, using 2000 or 7000 series materials, are strengthened through heat treatment.

- Outer Panels: Secondary load-bearing areas, using 5000 or 6000 series materials.

- Doors: Using 5000 or 6000 series materials.

- Floors: Using 5000 or 6000 series materials.

About SogaWorks

SogaWorks is an all-in-one online platform for custom mechanical parts, connecting over 1,000 top-tier factories to serve startups and major companies. We offer flexible manufacturing solutions for rapid prototyping, small-volume testing, and large-scale production with services like CNC machining, 3D printing, urethane casting, and injection molding. With our AI-powered quoting engine, SogaWorks can deliver quotes in 5 seconds, match the best capacity, and track every step. This cuts delivery times and boosts product quality.