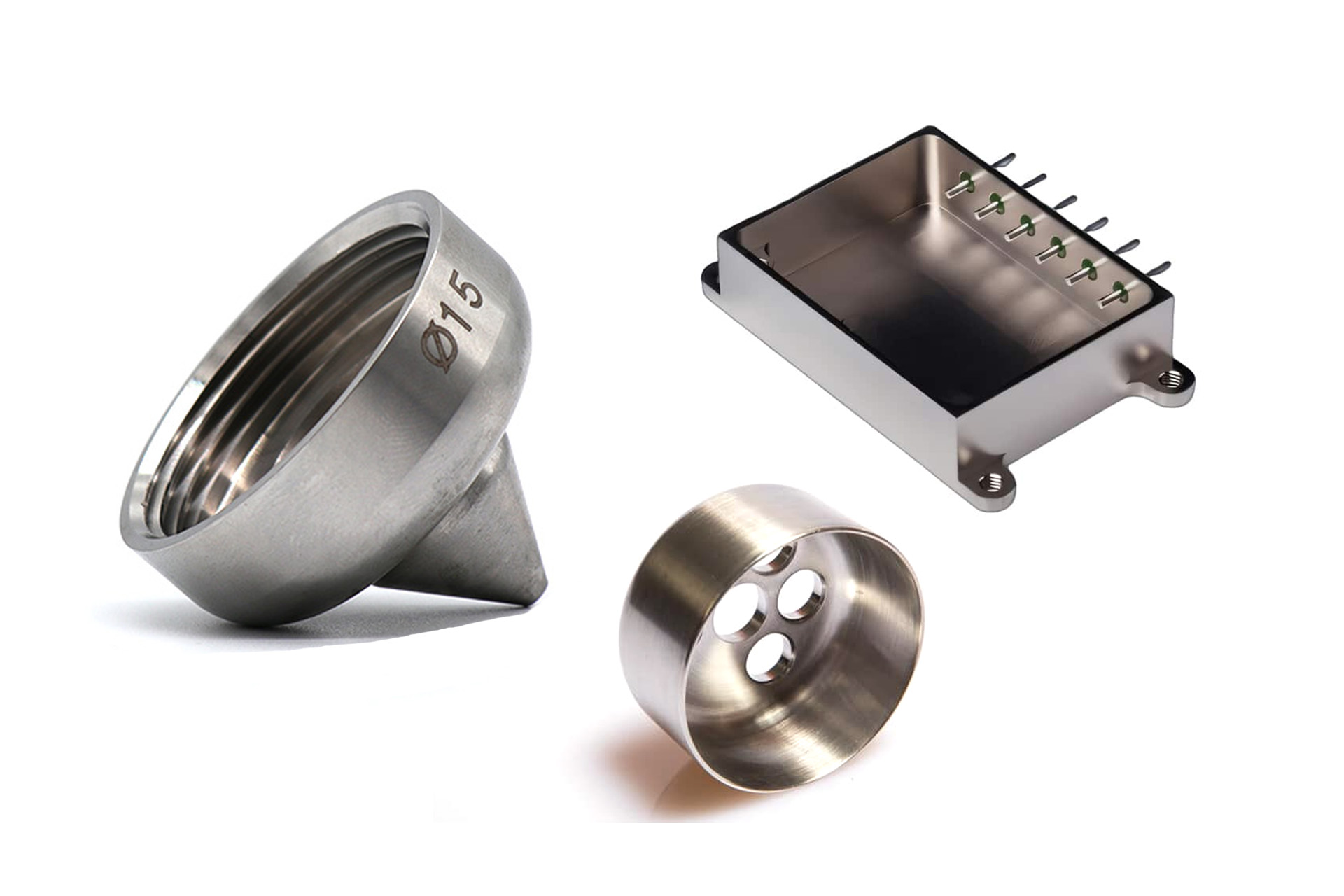

Kovar Machining Service

Kovar is an iron-nickel-cobalt alloy with an austenitic microstructure. Kovar can be formed into complex shapes with stamping and machining.

All drawings are secure and confidential.

What is Kovar?

Kovar alloy is a nickel, cobalt, and iron(Ni-Co-Fe) alloy, with nickel and cobalt being the main components and iron serving as an additive. When heated, Kovar alloy absorbs heat and expands, creating microscopic voids within the structure. These microscopic voids can enhance electrical conductivity while reducing magnetic permeability. Due to its unique thermal expansion properties.

Iron(Fe) |

Nickel(Ni) |

Cobalt(Co) |

Manganese(Mn) |

Silicon(Si) |

|---|---|---|---|---|

|

28%~29% |

29% |

17% |

~0.5% |

~0.2% |

Advantages of Kovar in Machining

Advantages

- The thermal expansion coefficient of Kovar is very low and closely matches most glass materials. This means that Kovar maintains dimensional stability when temperatures change.

- Excellent mechanical properties: Kovar has high strength and hardness, making it suitable for manufacturing high-precision instruments and equipment. Additionally, Kovar has good toughness and tensile strength, capable of withstanding significant impact and vibration.

- Corrosion resistance: Kovar has good corrosion resistance to water and some chemicals

- Realiable Sealing: Kovar's capacity to create hermetic seals with glass/ceramics is invaluable for protecting electronics from environmental factors that can cause failure.

Notes

- Thermal Management: Kovar alloy holds onto heat, which can be a pain during CNC machining because it might cause overheating. Using good cooling tricks is super important to keep tools from wearing out and to make sure parts come out just right.

- Material Hardness: Kovar gets tougher as you cut it, which makes machining a bit of a struggle. This can wear down tools quicker and make it tough to get those really precise measurements.

- Precision Control: To get the spot-on accuracy needed for Kovar parts, you have to be really careful with the machining process. Choosing the right tools and adjusting the cutting settings just so are key to hitting the tight specs these parts usually need.

Properties of Kovar Alloy 4J29

4J29 alloy has a linear expansion coefficient similar to that of silicon borosilicate hard glass between 20°C and 450°C, with a high Curie point and excellent low-temperature structural stability. The oxide film on the alloy surface is dense and can be well wetted by glass. It does not react with mercury, making it suitable for use in instruments containing mercury discharge. It is a primary sealing material for electronic vacuum devices. Its mechanical properties in the annealed condition are as below:

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

|---|---|---|---|

|

340 MPa |

520 MPa |

42% |

68 HB |

Kovar Machining Process

Kovar alloy is commonly used because its coefficient of thermal expansion is close to that of glass and ceramics. When machining Kovar alloy, due to its unique physical and mechanical properties, special attention needs to be paid to the machining method and process.

- CNC Milling: Kovar alloy has high hardness and wear resistance, so it is necessary to pay attention to the selection of cutting tools and the optimization of cutting parameters.

- Heat Treatment: Heat treatment is a key method for adjusting the performance of 4J29 Kovar alloy. Proper annealing can reduce the alloy's hardness, improve its plasticity and toughness, providing a better performance foundation for subsequent processing and applications.

- Welding: It has excellent welding properties and is easy to arc weld, resistance weld, and braze. When arc welding 4J29, use Ni-Cr stainless steel coated with flux as the electrode.

- Due to its good malleability, CNC machining Kovar alloy is challenging as the material is easy to stick to the tools. Therefore, special coated tools must be used to ensure that the high-quality final parts.

- Pay attention to heat dissipation during Kovar alloy processing. Kovar alloy generates significant heat during machining. Proper heat dissipation not only improves efficiency but extends tool life.

- Surface treatment of Kovar alloy can improve its corrosion resistance and surface quality. Common surface treatment methods include oxidation, phosphate treatment and chemical plating.