Urethan-Guss-Service

- Schnelles Mock-up in nur 2 Tagen

- Urethanguss in kleinen Mengen ohne Werkzeugkosten

- Vollständige Inspektion vor der Auslieferung

Angebot für Urethan-Guss starten

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

Alle Zeichnungen sind sicher und vertraulich.

Urethan-Gießverfahren

Schnelles Mock-up

In weniger als 2 Tagen

Urethan-Guss

Urethanguss in kleinen Stückzahlen ohne Werkzeugkosten.

Oberflächenveredelung

Malerei, Siebdruck, Lasermarkierung.

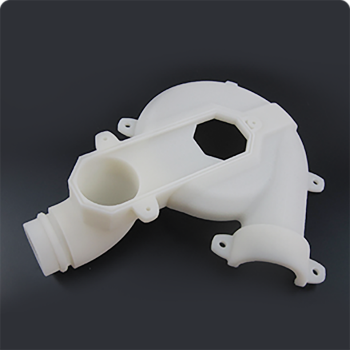

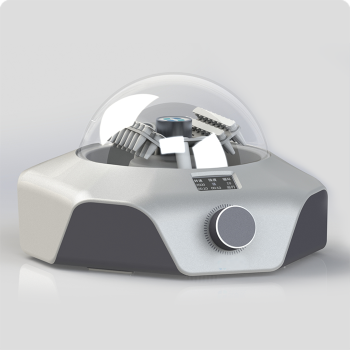

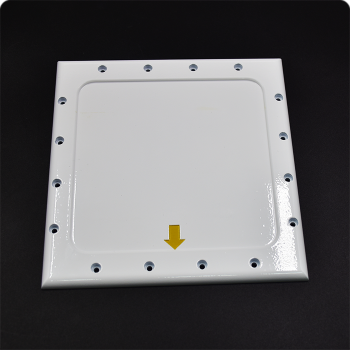

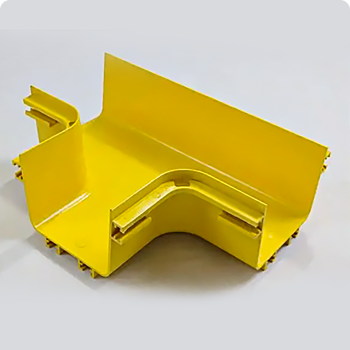

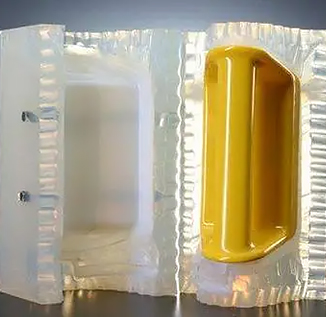

Von SogaWorks hergestellte Urethan-Gussteile

Galerie von Urethanguss-Prototypen und Endverbrauchsteilen, die wir für unsere geschätzten Kunden hergestellt haben.

Urethan-Guss-Toleranz

Das Urethangießen ist ein Fertigungsverfahren, bei dem Silikonformen zur Herstellung von Elastomerteilen in Produktionsqualität mit 10-200 Stück verwendet werden. In der Regel wird ISO 2768-m als Fertigungsnorm verwendet, und aufgrund der Wärmeausdehnung der Flüssigkeit und der Reaktion der flexiblen Form ist mit einer Schrumpfungsrate von +0,15% zu rechnen.

Grenzwerte für Nennlängen |

ISO 2768-m |

|---|---|

|

0,5 mm bis 3 mm |

±0,1mm |

|

Über 3 mm bis 6 mm |

±0,1mm |

|

Über 6 mm bis 30 mm |

±0,2mm |

|

Über 30 mm bis 120 mm |

±0,3mm |

|

Über 120 mm bis 400 mm |

±0,5 mm |

|

Über 400 mm bis 1000 mm |

±0,8 mm |

|

Über 1000 mm bis 2000 mm |

±1,2mm |

|

Über 2000mm bis 4000mm |

±2,0 mm |

Urethan-Gusswerkstoffe

Kunststoffe

Wir führen eine exklusive Auswahl an Kunststoffen für Urethan-Gussteile.

- ABS-ähnlich

- Acryl-ähnlich

- Nylonähnlich

- PC-ähnlich

- PP-ähnlich

- Gummiartig

- Klar gummiartig

Oberflächenbehandlungen

Malerei

Sprühen Sie eine Farbschicht auf die Oberfläche des Werkstücks.

Auftragen einer schützenden und dekorativen Beschichtung auf Materialien.

Pulverbeschichtung

Siebdruck

Bringen Sie Bilder, Muster oder Text auf Oberflächen an.

Verwenden Sie einen Laserstrahl, um die Oberfläche zu verändern und Materialien zu beschriften, zu gravieren oder mit Informationen zu versehen.

Lasermarkierung

Fertigungskapazitäten und Ausrüstung

- Mehr als 30 Länder und Regionen

- Mehr als 50.000 Kunden

- Insgesamt über 16.000.000 Teile hergestellt

- 1.000+ kooperierende Partnerfabriken

- 4.800+ Präzisionsgeräte

Was unsere Kunden sagen

Es war eine großartige Erfahrung, mit den Mitarbeitern von SogaWorks zu arbeiten. Sie sind sehr professionell und fürsorglich und halten eine reibungslose Kommunikation über unsere ausgelagerte Teileproduktion aufrecht. Wir werden auch bei zukünftigen Projekten mit ihrem Service zusammenarbeiten.

Wir haben viele Projekte für kleine Stückzahlen. SogaWorks hat unsere Anfragen immer fair behandelt. Darüber hinaus haben sie uns wertvolles technisches Feedback gegeben. Wir schätzen ihren aufrichtigen Wunsch zu helfen sehr.

Postdoc-Stipendiat, Universität Stanford

SogaWorks beweist Professionalität. Sie haben unseren Einkaufsprozess vereinfacht. Wir müssen uns nicht mit der Verwaltung verschiedener Lieferanten herumschlagen. Sie retten uns den Tag. Großartige Arbeit!

Einkaufsspezialist, Panasonic China

Wir möchten uns für Ihre unkomplizierte Unterstützung bei unseren Eilaufträgen bedanken. Unsere Anforderungen waren streng, und die Lieferfristen waren knapp bemessen. Dennoch wurden alle Aufträge perfekt ausgeführt. Das ist ein Team, das anspruchsvolle Aufträge annehmen kann.

Projektleiter, HP

Unsere Vorteile

Zitat in 5 Sekunden

Durch den Einsatz eines selbst entwickelten, auf maschinellem Lernen basierenden intelligenten Angebotssystems können wir Ihnen innerhalb von 5 Sekunden ein schnelles Angebot für Ihre Anfrage unterbreiten.

One-Stop Manufacturing Service

Wir bieten Fertigungsdienstleistungen aus einer Hand, von F&E-Prototypen bis zur Massenproduktion, für Hunderte von Materialien und die meisten Oberflächenbehandlungen.

Professioneller End-to-End-Service

Unsere spezialisierten Kundenbetreuer und Ingenieure bieten einen "One-to-One"-Service und arbeiten mit Kunden und Partnern zusammen, um deren Anforderungen besser zu verstehen und so eine bessere Durchlaufzeit und niedrigere Kosten für Ihr Projekt zu erreichen.

Vor der Auslieferung vollständig inspiziert

Bevor wir die Teile an Sie ausliefern, führen wir eine strenge Endkontrolle aller Teile mit hochpräzisen Messgeräten durch.

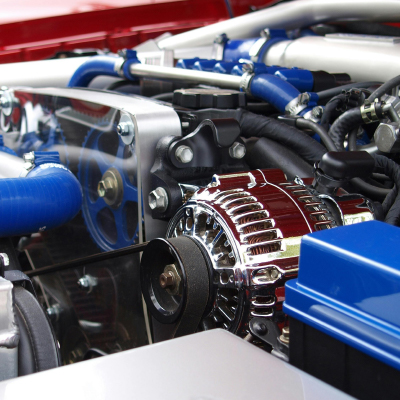

Für mehrere Branchen tätig

Unsere Dienstleistungen im Bereich Rapid Prototyping und On-Demand-Produktion werden in einer Vielzahl von Branchen eingesetzt, aber in den folgenden Bereichen haben wir die meiste Erfahrung.

Medizinische

Erhöhen Sie die Zuverlässigkeit Ihrer medizinischen Geräte mit einer präzisen Fertigungslösung.

Luft- und Raumfahrt

Leichte und langlebige Lösungen für die anspruchsvollsten Anforderungen in der Luftfahrt.

Automobilindustrie

Maßgeschneidert für optimale Leistung und Zuverlässigkeit in der Automobilindustrie.

Robotik

Treiben Sie Ihre Robotik-Innovationen mit unseren präzisionsgefertigten Teilen voran.

FAQs über den Urethanguss-Service

Wie lange ist die Vorlaufzeit für den Urethanguss?

Der Urethanguss auf Produktionsniveau hat normalerweise eine Vorlaufzeit von 3 Wochen. Obwohl das Urmodell und die Form in 1 bis 2 Tagen fertiggestellt werden können, kann es aufgrund der Aushärtungszeit des Urethans, die nicht verkürzt werden kann, länger dauern, bis das Produktionsvolumen erreicht ist. Eine einzelne Urethangussform produziert normalerweise 1-10 Teile pro Tag, abhängig von Faktoren wie der Art des Urethans und der Teilegeometrie.

Wie funktioniert der Urethanguss?

Das Urethangießen ist ein Herstellungsverfahren, bei dem eine Form anhand eines Urmodells oder Modells, in der Regel aus Silikonkautschuk, hergestellt wird. Anschließend wird ein Gemisch aus Urethanharz und einem Aushärtemittel in den Hohlraum der Form gegossen, wobei darauf zu achten ist, dass dieser vollständig ausgefüllt wird und alle Luftblasen entfernt werden. Das Urethan härtet bei Raumtemperatur oder in einem Ofen aus. Sobald es ausgehärtet ist, wird die Form geöffnet, das Gussteil entnommen und von überschüssigem Material befreit.

Wie groß sind die Toleranzen beim Urethanguss?

Die Toleranzen für gegossenes Urethan liegen normalerweise bei ± 0,015" oder ± 0,003 pro Zoll, je nachdem, welcher Wert größer ist. Von Fall zu Fall können auch engere Toleranzen vorgesehen werden. Im Allgemeinen beträgt eine typische Schrumpfungsrate +0,15%.

Was ist der Unterschied zwischen Urethangießen und Spritzgießen?

Beim Urethanguss werden flüssige Urethanharze verwendet, die in eine Form gegossen werden, während beim Spritzguss geschmolzener Kunststoff in eine Form gespritzt wird. Urethangussformen bestehen in der Regel aus Silikonkautschuk oder anderen weichen Materialien, während Spritzgussformen aus Stahl oder Aluminium hergestellt werden und wesentlich robuster sind. Das Urethangießen eignet sich für kleine bis mittlere Produktionsmengen, während das Spritzgießen besser für die Großserienproduktion geeignet ist. Außerdem können beim Spritzgießen Teile mit gleichmäßigeren Abmessungen und engeren Toleranzen hergestellt werden, allerdings sind die Vorlaufkosten für die Werkzeugherstellung wesentlich höher.