ウレタン鋳造サービス

- 最短2日でのラピッドモックアップ

- 金型代不要の少量ウレタン鋳造

- 納品前の全数検査

ウレタン鋳造の見積りを開始

ステップ i stp i sldprt i prt i ipt i dwg i pdf i dxf i zip i rar

すべての図面は安全かつ機密です。

ウレタン鋳造プロセス

ラピッド・モックアップ

最短2日

ウレタン鋳造

金型代不要の少量ウレタン鋳造。

表面仕上げ

絵画、シルクスクリーン、レーザーマーキング。

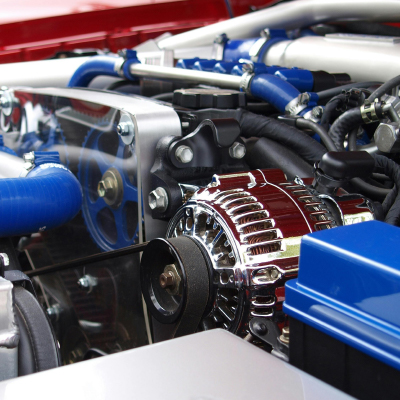

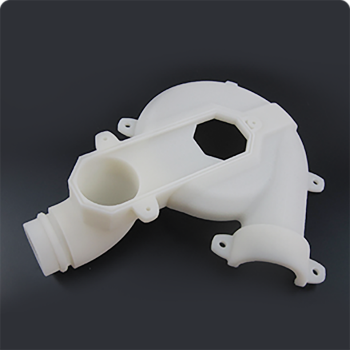

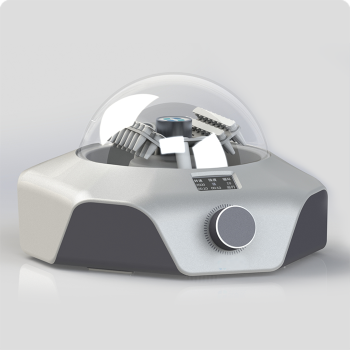

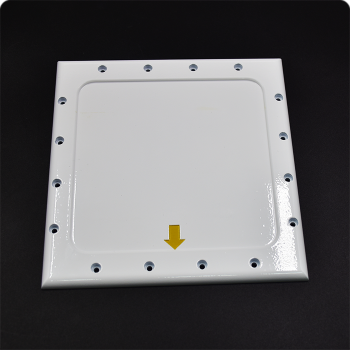

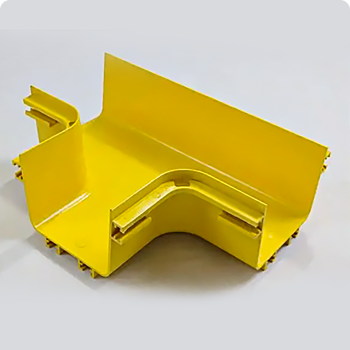

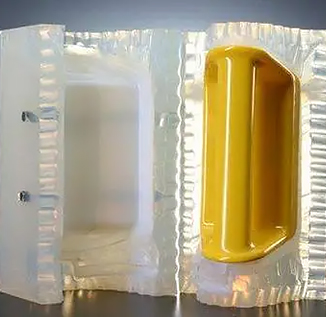

曽我製作所のウレタン鋳造部品

ウレタンキャストのプロトタイプと最終使用部品のギャラリーです。

ウレタン鋳造公差

ウレタンキャスティングは、シリコーン型を使用して10~200個の生産グレードのエラストマー部品を製造する製造プロセスです。通常、ISO 2768-mが製造標準として使用され、液体の熱膨張と柔軟な金型の反応により、+0.15%の収縮率が予想されます。

公称長さの限界 |

ISO 2768-m |

|---|---|

|

0.5mmから3mm |

±0.1mm |

|

3mm以上6mm未満 |

±0.1mm |

|

6mm以上30mm以下 |

±0.2mm |

|

30mm以上120mm以下 |

±0.3mm |

|

120mm以上400mm以下 |

±0.5mm |

|

400mm以上1000mm未満 |

±0.8mm |

|

1000mm以上2000mm未満 |

±1.2mm |

|

2000mm以上4000mm未満 |

±2.0mm |

ウレタン鋳造材料

プラスチック

当社では、ウレタン鋳造部品用のプラスチック材料を独占的に取り揃えています。

- ABSライク

- アクリルライク

- ナイロンライク

- PCライク

- PPライク

- ゴムのような

- 透明なラバーライク

表面仕上げ

絵画

パーツの表面に塗料をスプレーする。

素材に保護と装飾のためのコーティングを施す。

パウダーコーティング

シルクスクリーン

画像、パターン、テキストを表面に貼り付ける。

レーザー光線を使用して表面を加工し、ラベルを貼ったり、彫刻したり、材料に情報を追加したりする。

レーザーマーキング

製造能力 設備

- 30以上の国と地域

- 50,000人以上の顧客

- 合計16,000,000個以上の部品を製造

- 1,000以上の協力工場

- 4,800台以上の精密機器

お客様の声

SogaWorksの皆さんと仕事ができたことは素晴らしい経験でした。彼らはとてもプロフェッショナルで思いやりがあり、外注部品の生産に関してもスムーズなコミュニケーションを保ってくれます。今後のプロジェクトでも、SogaWorksのサービスを利用するつもりです。

私たちは少量部品のプロジェクトがたくさんあります。ソガワークスさんには、いつも公平に対応していただいています。さらに、貴重な技術的フィードバックもいただきました。本当に感謝しています。

スタンフォード大学 博士研究員

ソガワークスはプロフェッショナリズムを発揮してくれます。SogaWorksのおかげで、購買プロセスが楽になりました。様々なサプライヤーを管理するのに苦労することはありません。本当に助かりました。素晴らしい仕事ぶりです!

パナソニック中国、購買スペシャリスト

急ぎの注文にもかかわらず、誠実に対応していただき感謝しています。私たちの要求は厳しく、納期はタイトでした。しかし、すべての注文は完璧に納品されました。このチームは困難な仕事も引き受けることができます。

プロジェクト・マネージャー、HP

当社の強み

5秒で引用

自社開発の機械学習によるインテリジェントな見積もりシステムを活用することで、お客様のお問い合わせに対して5秒で迅速な見積もりを提示することができます。

ワンストップ製造サービス

研究開発の試作品から大量生産まで、ワンストップで製造サービスを提供し、数百種類の素材とほとんどの表面仕上げをカバーしています。

エンド・ツー・エンドのプロフェッショナル・サービス

当社の専門アカウントマネージャーとエンジニアは、「One to One」サービスを提供し、お客様やパートナーの要件をよりよく理解することで、お客様のプロジェクトの納期短縮とコスト削減を実現するため、協力的に取り組んでいます。

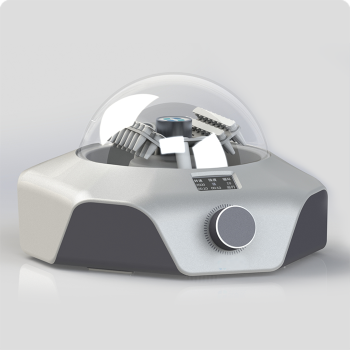

配達前の完全検査

お客様に出荷する前に、高精度の測定器を用いて、すべての部品について厳密な最終検査を行います。

多業種に対応

私たちのラピッドプロトタイピングとオンデマンド生産サービスは、幅広い業界で利用されていますが、最も多くの経験を積んでいるのは以下の分野です。

ウレタン鋳造サービスに関するFAQ

ウレタン鋳造のリードタイムはどのくらいですか?

生産レベルのウレタン鋳造のリードタイムは通常3週間です。マスターパターンと金型は1~2日で完成しますが、ウレタンの硬化時間は短縮できないため、生産量を満たすにはさらに時間がかかります。ウレタン鋳造用金型1つで、ウレタンの種類や部品の形状などの要因にもよりますが、通常1日に1~10個の部品を生産します。

ウレタンキャスティングの仕組み

ウレタンキャスティングは、一般的にシリコンゴムで作られたマスターパターンや模型を使って型を作る製造工程です。その後、ウレタン樹脂と硬化剤の混合物を型の空洞に流し込み、完全に充填されたことを確認し、気泡を取り除きます。ウレタンは室温またはオーブンで硬化するまで放置され、硬化したら型を開き、鋳造部品を取り出して余分な材料を切り落とします。

ウレタン鋳造の公差は?

鋳造ウレタンの公差は通常、約±0.015インチまたは±0.003/インチのいずれか大きい方です。ケース・バイ・ケースで、より厳しい公差が提供される場合もあります。一般的な収縮率は+0.15%です。

ウレタン鋳造と射出成形の違いは何ですか?

ウレタンキャスティングは液状のウレタン樹脂を型に流し込み、射出成形は溶かしたプラスチックを型に注入して成形します。ウレタンキャスティングの金型は一般的にシリコンゴムなどの柔らかい素材でできていますが、射出成形の金型は鉄やアルミでできており、耐久性に優れています。射出成形は大量生産に向いています。また、射出成形は、より安定した寸法と厳しい公差の部品を製造できますが、金型の初期費用がはるかに高くなります。