CNC加工におけるアルミニウム

当社の合金と材種の選択で、アルミニウムのCNC加工を探求してください。アルミニウムは、汎用性が高く、軽量で、強く、耐久性があり、航空宇宙や自動車など多くの産業で使用されています。

すべての図面は安全かつ機密です。

メリット

- 強度重量比:軽量でありながら、驚くほど高い強度を実現。

- 耐食性:さまざまな環境条件下で自然な耐食性を発揮します。

- 加工性:柔らかく欠けやすいため、成形や加工が容易。

- カスタム仕上げ:アルミニウム部品は幅広い表面仕上げに対応しています。

備考

- 材料の特性: 柔らかく延性のある金属で、加工中に変形したり反ったりしやすい。

- 表面仕上げ:複雑な形状やフィーチャーを加工する場合、滑らかで一貫した表面仕上げを達成するのは難しい。

- バリや鋭いエッジ:アルミニウムは加工中に鋭いバリやエッジを生じることがある。

使用可能な合金と等級

アルミニウム 2024

航空宇宙グレードの素材であるアルミニウム7075-T6は、卓越した強度対重量比、高強度、高硬度を誇ります。

- 引張強度:425 MPa

- 降伏強度:275 MPa

- 破断伸度14%

- 硬度:120HB

アルミニウム6061

アルミニウム6061は、最も人気のあるアルミニウム合金で、強度、溶接性、耐食性のバランスがとれています。

- 引張強度:290 MPa

- 降伏強さ: 240 MPa

- 破断伸度9%

- 硬度:95HB

アルミニウム 6063

アルミニウム6063は優れた機械的特性を持ち、熱処理が可能です。一般的に構造用途に利用されている。

- 引張強度:205 MPa

- 降伏強度:170 MPa

- 破断伸度9%

- 硬度:75HB

アルミニウム 7075

航空宇宙グレードの素材であるアルミニウム7075-T6は、卓越した強度対重量比、高強度、高硬度を誇ります。

- 引張強度:540 MPa

- 降伏強度:475 MPa

- 破断伸度8%

- 硬度:150HB

アルミニウム MIC-6

アルミニウムMIC-6は軽量であるため、高速加工が容易であり、張力、汚染物質、気孔の発生がない。

- 引張強度:116 MPa

- 降伏強度:105 MPa

- 破断伸度5%

- 硬度:65HB

* 一般的な値。参考値。

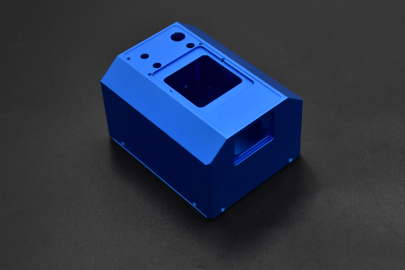

仕上げと後処理オプション

SogaWorksは、アルミニウム合金に合わせた表面仕上げの幅広い選択肢を提供しています。中でもアルマイト処理は、ノーマルコーティングとハードコーティングの両方のオプションがあり、最も好まれている処理です。これらの処理により、アルミニウム合金の耐摩耗性と耐食性が大幅に向上します。

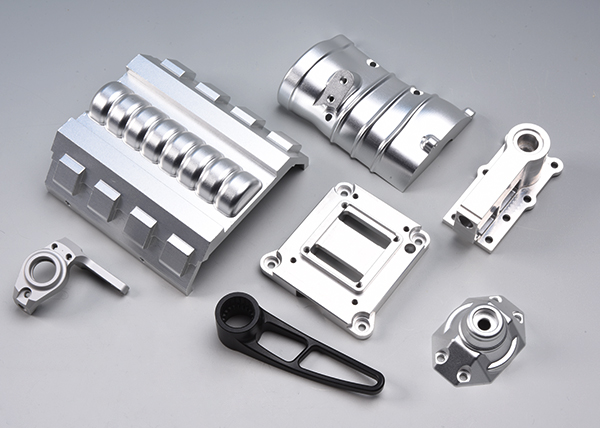

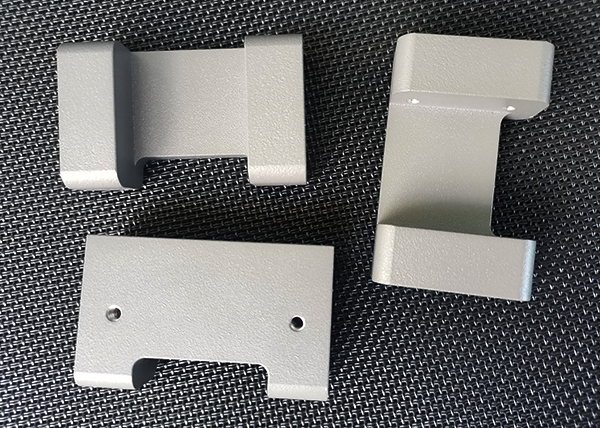

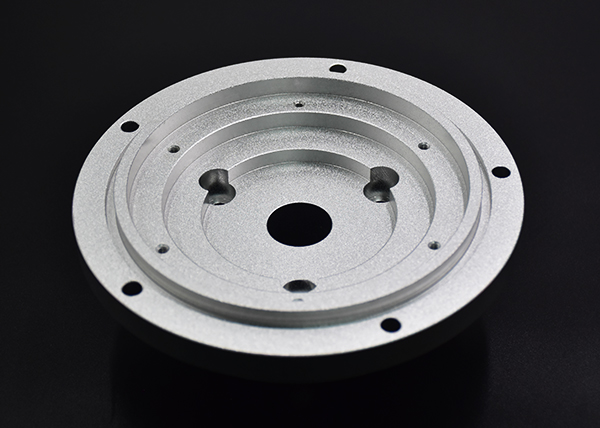

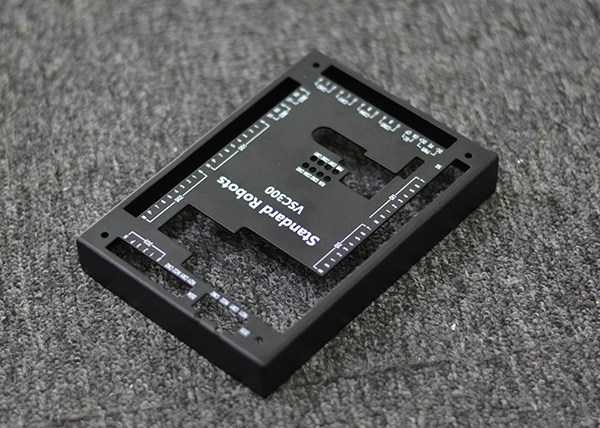

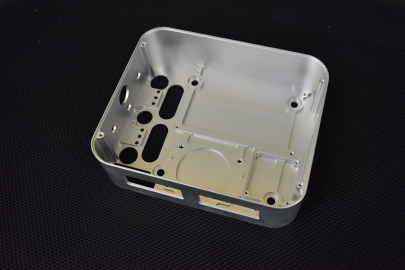

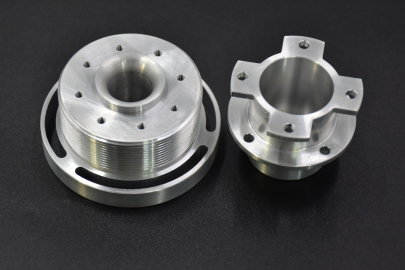

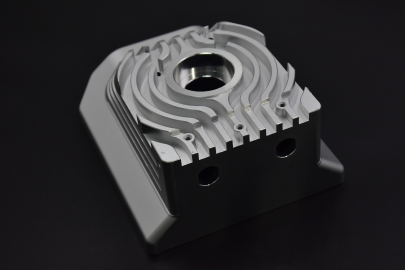

CNC加工アルミニウム部品のギャラリー

よくある質問 アルミニウムCNC加工について

アルミニウムCNC加工のコストは、使用する合金の種類、部品の複雑さ、必要な公差、表面仕上げ、バッチサイズ、加工時間などの要因によって異なります。当社は、お客様のプロジェクトのニーズに合わせた競争力のある価格設定を提供します。

はい、アルミニウム合金は、加工設備、工具、部品の形状にもよりますが、±0.01mm以内の厳しい公差でCNC加工できます。公差が指定されていない場合は、以下の条件でアルミニウム部品を加工します。 ISO2768規格.

アルミニウム合金は、以下のような様々な表面処理で仕上げることができる。 陽極酸化タイプIIおよびタイプIII, 粉体塗装塗装、ビーズブラスト、研磨を施し、美観、耐食性、耐摩耗性を高める。