Common Materials in Non-standard Custom Manufaturing

In this article, we have listed 20 types of common materials in non-standard part custom manufacturing.

In this article, we have listed 20 types of common materials in non-standard part custom manufacturing.

Polyetheretherketone (PEEK), developed by Imperial Chemical Industries (ICI) in 1978, is a semi-crystalline, linear aromatic polymer composed of alternating ether bonds, aromatic rings, and carbonyl groups. This thermoplastic, ultra-high-performance engineering plastic boasts a molecular structure with numerous benzene rings, where the relatively flexible C-O bonds are effectively protected by the steric hindrance of two benzene

EDM uses electrical corrosion from pulsed discharges between a tool electrode and a workpiece electrode to process materials.

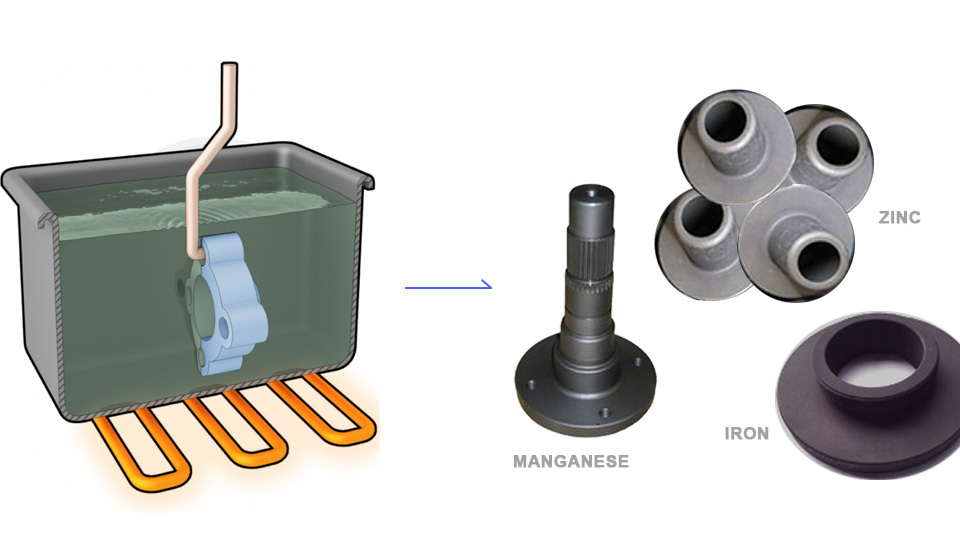

Phosphating is a process that forms a phosphate conversion coating on a metal surface through chemical and electrochemical reactions.

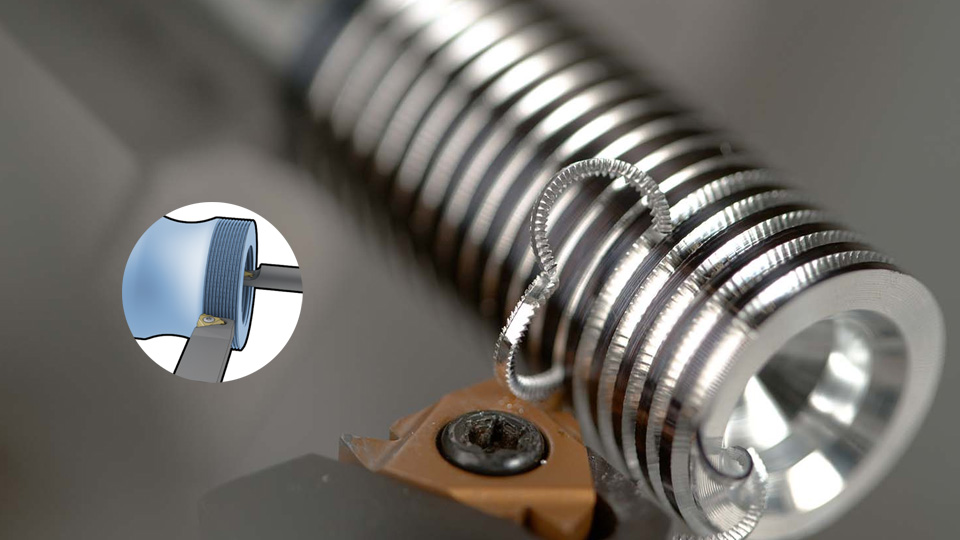

For connecting threads, processing methods include tapping, turning, rolling, and rubbing. For transmission threads, grinding, or cyclone milling.

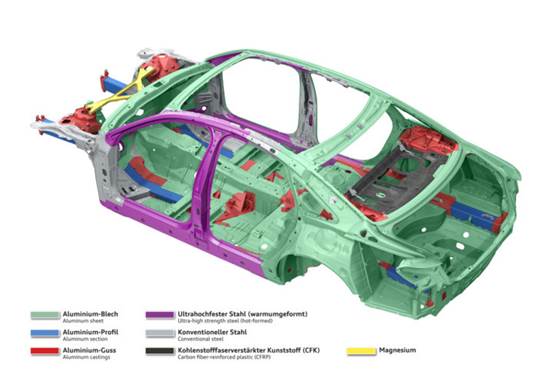

With technological advancements and growing market demand, aluminum usage in small to mid-sized vehicles has increased.

Aluminum is a soft, lightweight metal. The density of aluminum alloy depends on its alloying elements.

This article will introduce you to 9 basic mechanical properties of materials: strength, plasticity, hardness, toughness, fatigue, elasticity, stiffness, wear resistance, and corrosion resistance.

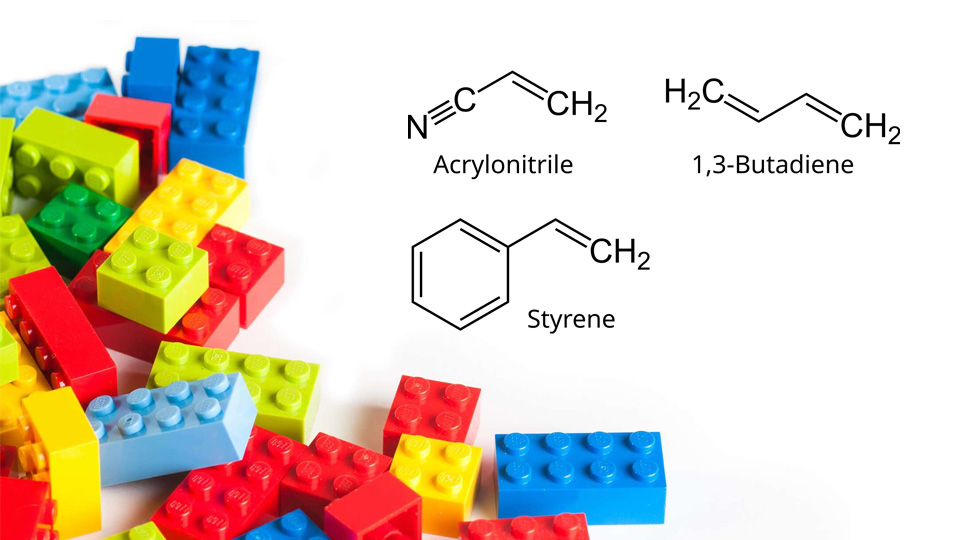

Acrylonitrile Butadiene Styrene (ABS) resin has balanced properties such as high strength, toughness, and versatility. This article will discuss its fundamental properties, classifications, performance characteristics, and processing techniques. What is ABS Plastic? ABS resin is a ternary copolymer composed of acrylonitrile (A), butadiene (B), and styrene (S), along with its modified variants. Plastics made from

住所

2号館101-117号室(1階全体)、

天心工業区国興区西翔街、

中国深セン市宝安区518126